- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

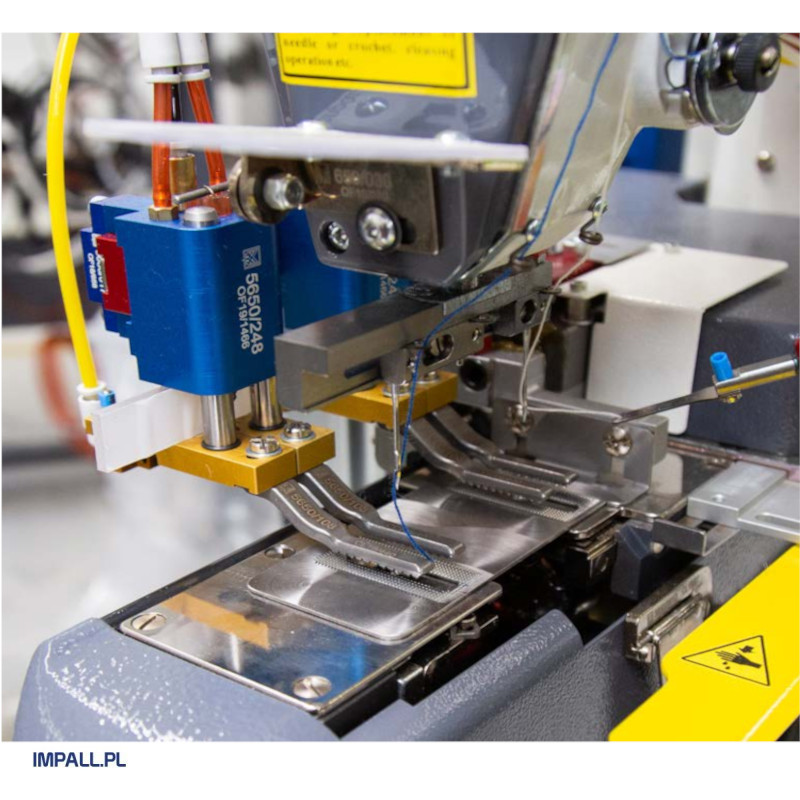

This automatic belt loop sewing machine is equipped with a two-needle sewing head that allows for simultaneous sewing of both bartacks on the belt loop. Automatically measuring, cutting, hemming, and sewing the belt loop in a single operation significantly improves the machine’s efficiency and ensures excellent repeatability and sewing quality.

Control is provided via a clear 7-inch touchscreen control panel with error diagnostics.

The operator’s work is limited to simply placing the item in the machine’s work area.

Key Features:

– Adjustable distance between the knife and the belt loop forming device allows for sewing on loops with a “lug” (ear)

– The sewing machine’s narrow cylinder allows for sewing on loops on small items (e.g., children’s clothing)

– The machine can also be used for working with stretch fabrics

– Possibility of creating decorative bartack patterns

– Large workspace between the machine and the feeder

– Compensating presser feet

Technical Specifications:

– Sewing speed up to 2,600 stitches/min

– Capacity: 1,600 pairs of trousers (5 belt loops per belt)

– Large capacity loopers

– Loop length: 32–85 mm

– Needle gauge: 25–80 mm

– Loop width: 8–30 mm (30 mm – special parts required)

– Touchscreen control panel

– Automatic detection and cutting of thickening (tape joints) on the belt belt loops

– Compressed air connection required

– Air consumption 6 l/min

– Operating pressure 4.5 bar

– 230V power supply