- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

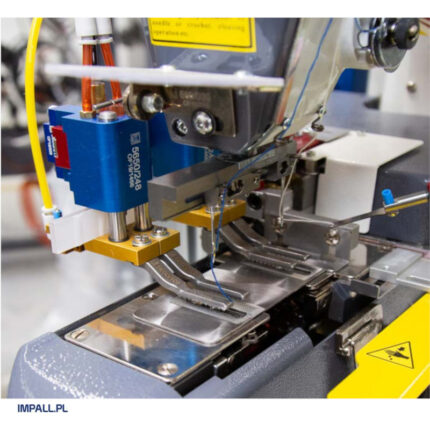

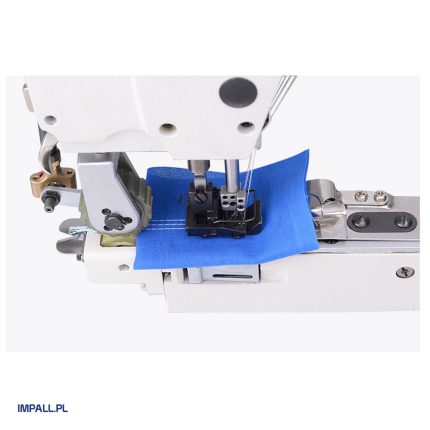

Three-needle arm machine with chain stitch, designed for joining heavy materials with a French seam. Ideal for sewing denim, workwear, uniforms, etc. Unique solutions ensure the highest quality end result and a consistent stitch length, even on thicknesses.

The special patented belt puller placed directly behind the presser foot ensures stable and even material feed. Using the highest quality components allows for sewing at speeds of up to 4,999 stitches/min. The machine is equipped with a DCP system providing constant dynamic presser foot pressure control. The machine can adjust the pressure depending on the thickness of the sewn layers (cross seams, joints, etc.).

Automatic chain (thread) trimming further enhances work efficiency.

Various needle spacings are available as options. By default, the machine is adapted for sewing heavy materials, but it can also be adjusted for lighter materials.

The machine is mounted on a column base, ensuring convenient access to the work area.

Technical specifications:

- sewing speed up to 4,999 stitches/min

- stitch length 0.9 to 4.5 mm

- standard needle spacing 1/4” (6.4 mm)

- optional needle spacings 3/16” (4.8 mm, 2 needles) – 9/32” (7.2 mm) – 5/16” (8 mm) – 3/8” (9.6 mm) – 3/8” (9.6 mm, 1/4” 6.4 mm + 1/8” 3.2 mm)

- Vi.Be.Mac. 2 or 3-needle chain stitch head

- power supply 230V 50/60 Hz

- Mitsubishi XCG 754 20Y drive – 750W

- air consumption 3 L/min

Connection to compressed air is required.