- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

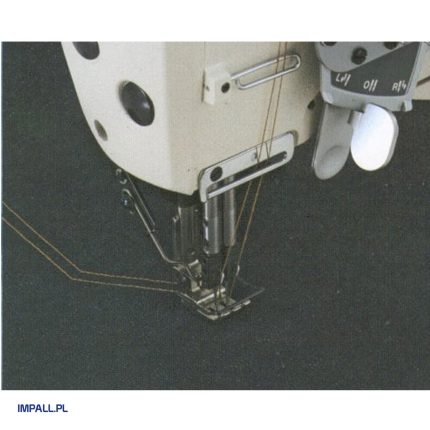

Flat-bed coverstitch binding machine equipped with a right-side knife to trim the fabric before attaching the binding. Designed for sewing underwear and sportswear. Binding with elastic is also possible. The machine sews with a 2-needle coverstitch with a bottom looper.

Technical specifications:

- Sewing speed: 4500 stitches/min

- Needle spacing: 4.0 mm (optional 3.2 mm)

- Number of needles: 2

- Stitch length: 1.6 – 3.2 mm

- Presser foot lift height: 5 mm

- Differential feed: 0.5 – 1.3

- Needle system: UY128GAS #10

- Power supply: 230V

The machine is standardly equipped with a modern energy-efficient servo motor mounted directly on the machine (Direct Drive system).

Additional options:

- Guillotine to cut the tape behind the presser foot

- Electronic elastic tensioner

Servo motors are currently the most advanced type of drive for sewing machines. Machines with this drive consume up to 75% less electricity compared to traditional motors, are quieter, and have less vibration during operation.