- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

2-Needle Lockstitch Machine Without Disengaging Needle Bars, Equipped with Small Hooks and Double Needle-Dog Feed, Programmable for Light Sewing with Automation

This 2-needle lockstitch machine is designed for sewing light and medium materials, featuring small hooks and double needle-dog feed without disengaging needle bars. The machine is equipped with a range of innovative solutions that enhance efficiency and work comfort. The powerful 750W Direct-Drive motor ensures quiet operation and low energy consumption. The DT828L is the first 2-needle machine by Siruba equipped with two stepper motors controlling material feed, thread trimming, and presser foot lifting. This configuration operates much quieter and more efficiently compared to traditional electromagnet-controlled mechanisms.

For improved work comfort, the machine includes powerful LED workspace lighting with 3-level brightness adjustment.

Features of the DT828L Machine:

- A special bidirectional stepper motor (patented) allows simultaneous control of thread trimming and presser foot lifting.

- A new straight thread trimming mechanism offers better performance and is easier to adjust.

- An enclosed lubrication system minimizes the risk of staining materials during sewing.

- The control panel allows easy management of automatic functions and setting of stitch and sewing parameters.

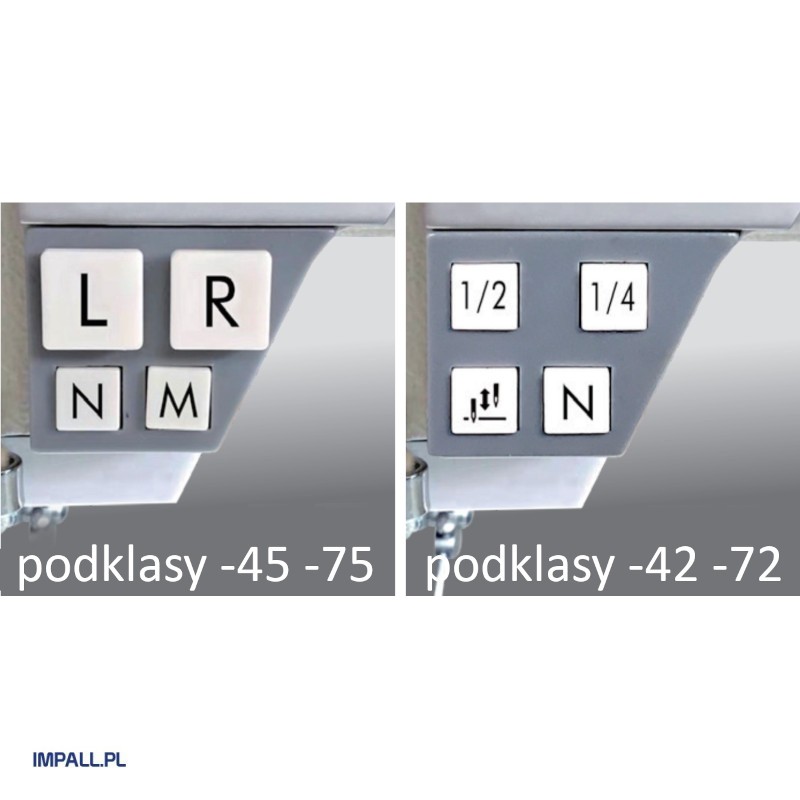

The machine is equipped with four function buttons next to the needle bar:

- Needle positioning/stitch adding

- Reverse sewing

- Stitch tightening 1/2 stitch

- Stitch tightening 1/4 stitch

The electronically controlled stitch length, managed by a stepper motor, ensures perfect stitching parameters, even during backtacking. It also enables programmable decorative stitches.

The electronic knee lifter controls the stepper motor that raises the presser foot, requiring less effort than mechanical knee lifters.

Technical Specifications:

- Sewing speed: 3,000 stitches/min

- Stitch length: 4 mm

- Standard needle spacing: 6.4 mm

- Presser foot lift height: up to 12 mm

- Needles: DPx5

- Power supply: 230V

The heavy-duty subclass -42 is equipped with hooks of standard capacity.