- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

Modern 1-Needle Lockstitch Machine with Needle-Feed, Drop-Feed, and Edge Trimmer

This modern 1-needle lockstitch machine features a double needle-feed and drop-feed transport system with an integrated edge trimmer, designed for sewing light to medium materials. It is ideal for precision sewing tasks such as flaps, cuffs, collars, and other detailed elements. The edge trimmer mechanism can be quickly engaged or disengaged, allowing for versatile operation without the constant need for trimming.

Equipped with an energy-saving servo motor, control box, and an integrated control panel in the machine head.

Automatic Functions:

- Thread trimming

- Backtacking at the start and end of sewing

- Needle positioning

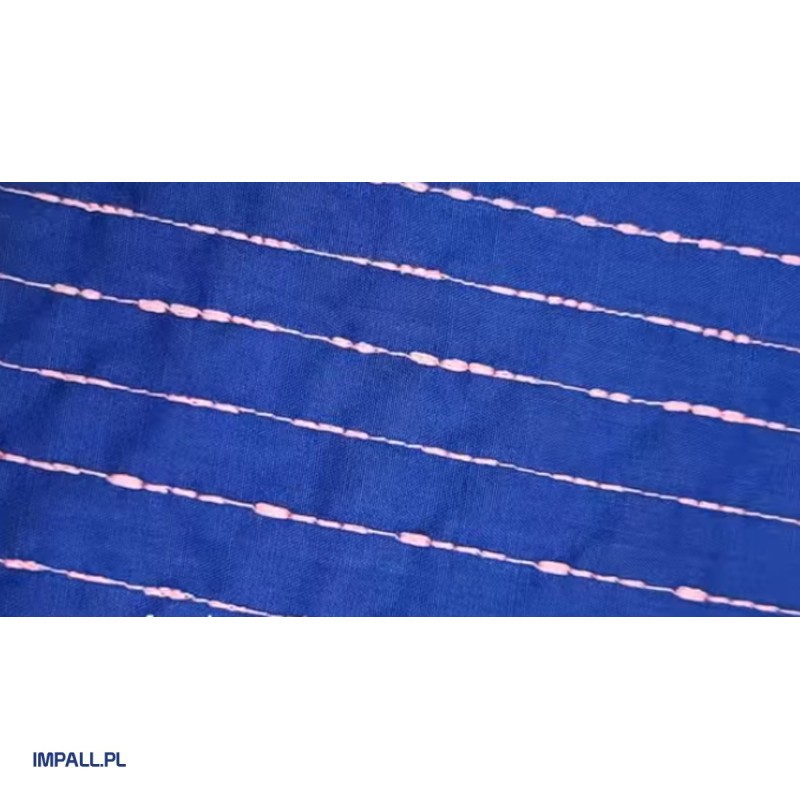

- Decorative stitch programming

- Stitch parameter programming

- Automatic presser foot lifting

The machine includes two stepper motors:

- One for controlling material feed, which allows for decorative stitching, quiet operation, perfect backtacking, and stitch condensing functions.

- Another for thread trimming and presser foot lifting, ensuring quiet performance.

The closed lubrication system minimizes the risk of oil contamination during operation, extending the intervals between oil changes. The machine is also equipped with a nipper to hold the thread at the start of sewing and three function buttons conveniently located next to the needle bar:

- Reverse sewing

- Stitch adding

- Stitch condensing

The needle-feed and drop-feed transport system aids in smooth material feeding, which is particularly crucial when sewing slippery materials, multiple layers, or sewing through thick sections.

Controlled via an easy-to-use touchscreen control panel. The electronic knee lifter allows for manual presser foot lifting. LED lighting illuminates the working area.

Technical Specifications:

- Sewing speed: 4,500 stitches/min

- Stitch length: 5 mm

- Presser foot lift height: 11 mm

- Cutting width: 4.8 mm (optional 3.2 mm or 6.4 mm)

- Needles: DBx1

- Power supply: 230V