- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

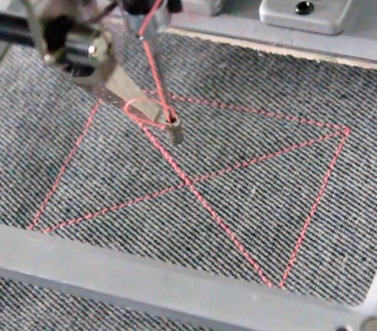

Electronically Controlled, Universal Programmable 2-Needle Bartack Machine with Large 80 x 60 mm Sewing Area

This electronically controlled, universal programmable 2-needle bartack machine is designed for sewing various materials. It features a presser foot that prevents fabric lifting during sewing. Equipped with a modern, energy-efficient 550W servo motor and stepper motors controlling the material and presser foot, the machine ensures smooth operation.

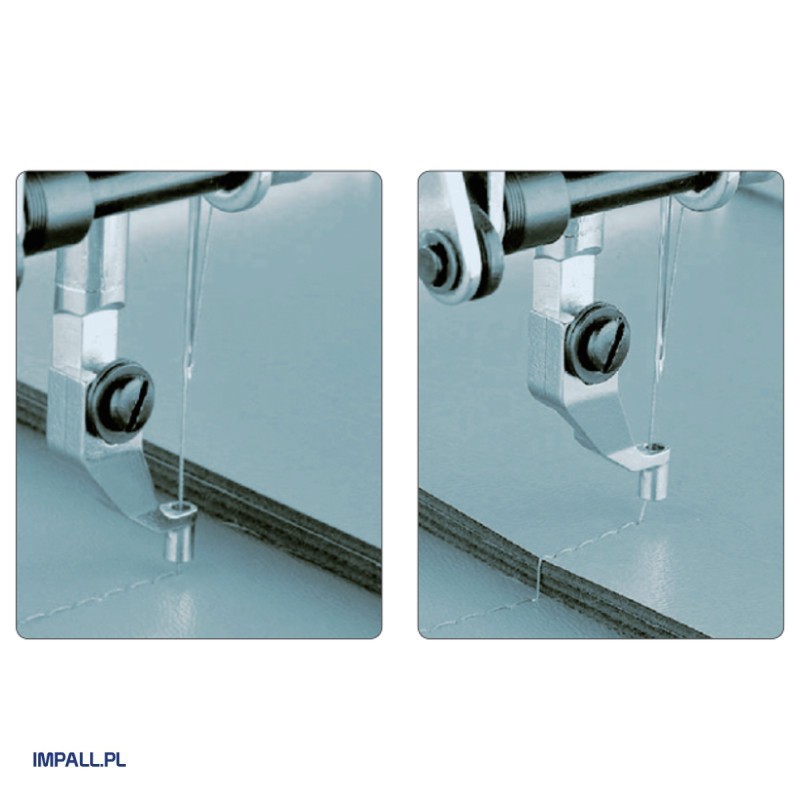

The improved lubrication system supplies oil only to the hook mechanism in a closed loop, avoiding lubrication of the needle bar drive mechanism. This design prevents any oil leakage from the upper part of the machine (commonly from the needle bar), thus avoiding fabric staining.

The 02A subclass is equipped with a pneumatically controlled split clamping frame that allows independent control of the left and right sides. This feature expands the machine’s application to a wider range of operations.

A new automatic thread trimming system leaves shorter threads on the fabric, enhancing seam aesthetics and eliminating the need for additional trimming. The machine includes a large, clear touch screen control panel that allows for creating custom stitching patterns. All icons and settings are clearly displayed, with smooth adjustment of stitch length and width. A USB port allows for copying patterns using portable memory.

Technical Specifications:

- Sewing speed: 3,000 stitches/min

- Standard working area: 80 x 60 mm

- Stitch length: 0.05 – 12.7 mm

- Maximum stitches per program: 5,000

- Presser foot lifting height: 17 mm with smooth adjustment

- Built-in patterns: 89 (memory capacity: 512 patterns/500,000 stitches)

- Needles: 135×5 or 135×17

- Power supply: 230V/50Hz

- Pneumatic control required: needs to be connected to a compressed air source

|

|

|