- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

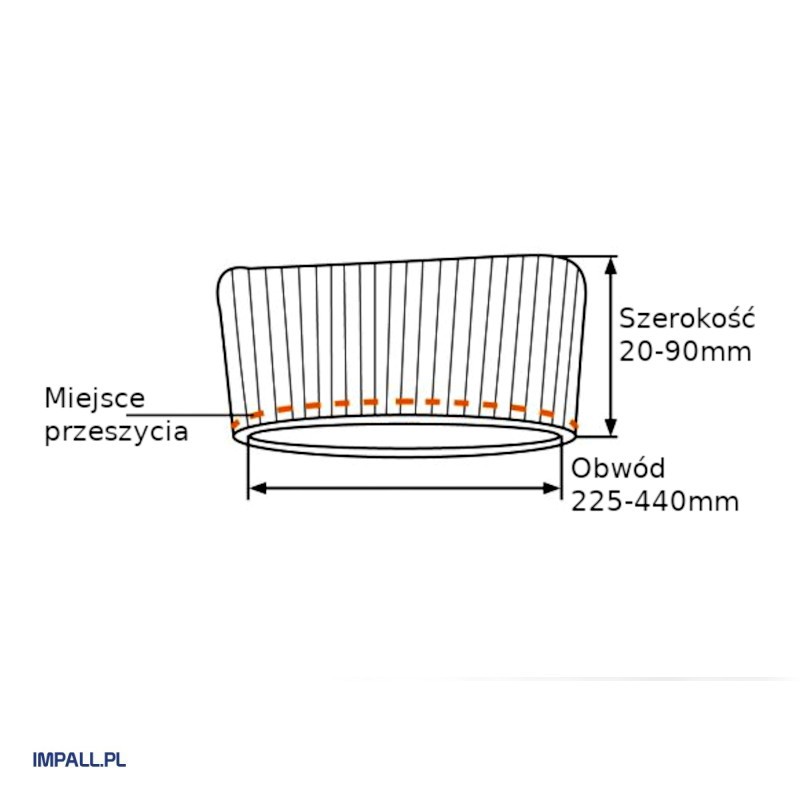

A modern automated machine designed for attaching cuffs to sleeves in sportswear or the legs of sweatpants. The specially designed cylindrical arm ensures even tension around the entire cuff circumference. The pneumatically controlled tensioning roller helps to stretch and hold the sewn elements.

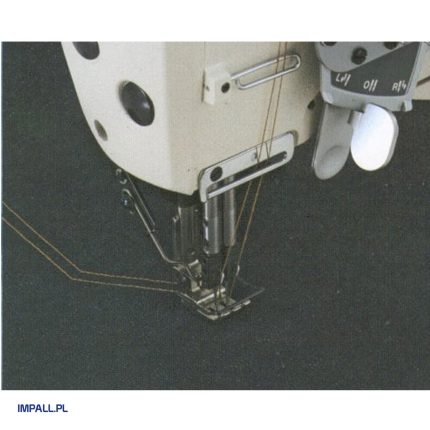

Automatic chain trimming, presser foot lifting, and a waste suction system contribute to high-quality and efficient sewing. A specially designed nozzle system, placed in front of the presser foot, prevents the edges of the sewn materials from curling. The machine is equipped with the high-performance Siruba 747KST cylindrical overlock head with dual feed (bottom + top). Control is managed through an easy-to-use, clear control panel.

Technical specifications:

- Sewing speed: 5,500 stitches/min

- Cuff width: 20 – 90 mm

- Cuff circumference: 225 – 440 mm

- Thickness of sewn materials: up to 6.5 mm

- Presser foot lift height: 8.0 mm

- Needles: B27 #11

- Working pressure: 0.5 MPa (air consumption: 35 l/min)

- Power supply: 230V

Performance: Cuff sewing time approximately 2 sec/piece (assuming a sewing speed of 3,000 stitches/min, cuff circumference of 270 mm, and cuff width of 60 mm).