- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

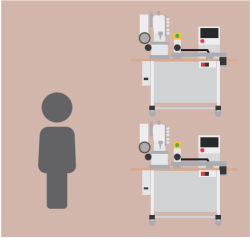

High-Efficiency Sewing Automation for Hemming T-Shirts and Polo Shirts

A high-performance chain stitch sewing automation designed for hemming the bottoms of T-shirts, Polo shirts, etc. The machine automatically positions the fabric under the presser foot, enabling a fully automatic hemming process without operator intervention.

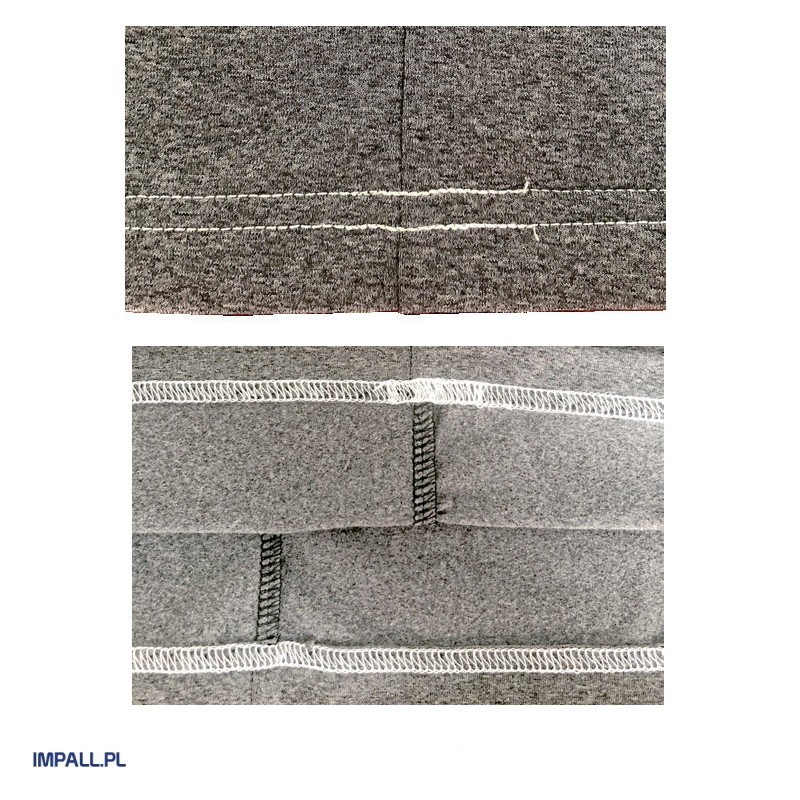

The machine features a Siruba C007KP cylindrical coverstitch head, which ensures high stitch quality and trims the edge of the folded fabric before stitching (bottom edge trimmer).

Automatic thread trimming, presser foot lifting, and trimming waste suction provide high-quality, efficient sewing. Controlled by an intuitive graphic touch panel for easy operation.

Automatic sewing parameter adjustments during size changes allow for seamless hemming of garments with different circumferences without manual setting adjustments.

- Automatic edge control

- Flattening system to manage rolled fabric edges

- End-of-thread sensors

- Edge trimming and waste suction for folded edges

- Automatic stacker for completed T-shirts

- Very easy to operate; no sewing skills required

- Single operator can handle two machines

Technical Specifications:

- Sewing speed: 4,000 stitches/min

- Needle spacing: 4.0; 4.8; standard 5.6 or 6.4 mm

- Hem width: 15 – 30 mm

- Efficiency: approximately 90-150 pcs/hr

- Garment width for hemming: 380 – 900 mm

- Needles: UY128GAS

- Power: 850W

- Power supply: 230V

- Weight: 180 kg

- Air consumption: 190 l/min, operating pressure: 4 bar

Connection to compressed air is required.