- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

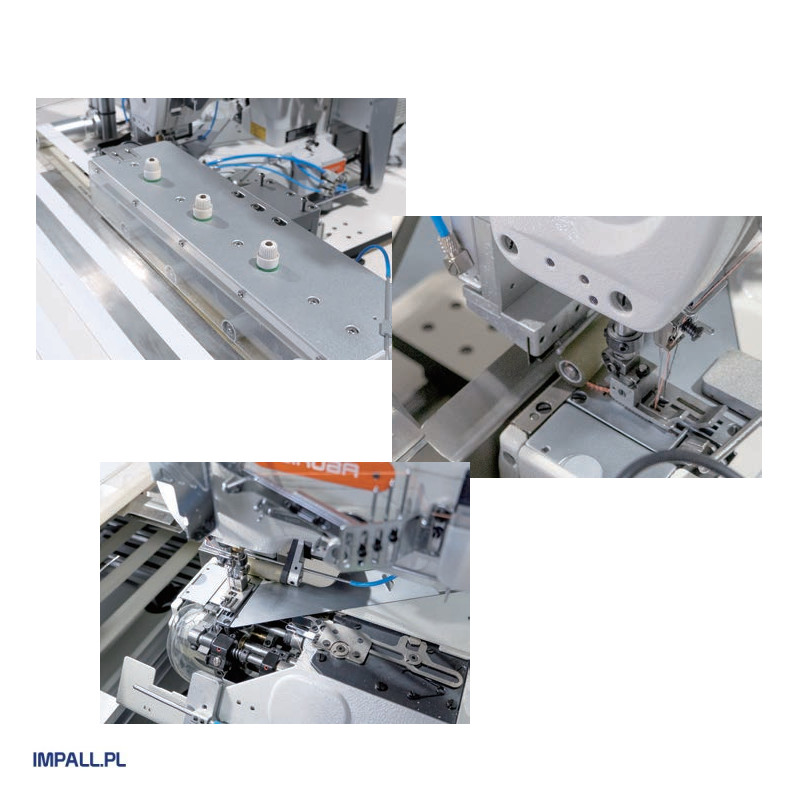

Fully automatic hemming station for garment edges such as sleeves, pockets, and hems of POLO shirts and T-shirts in a flat position. The machine is equipped with a Siruba C007L-W812A-356/CRL head that sews with a 2-needle coverstitch, along with a conveyor belt to guide the sewn materials. It features automatic hemming, trimming, and vacuuming of excess material, as well as thread trimming and a stacker that automatically arranges the finished pieces. These solutions ensure the highest quality, repeatability of stitches, and very high productivity. The automatic sewing process means the operator’s task is simply to place the garment pieces in the work area.

Advantages of production automation:

- Very easy to operate

- No sewing skills required to use the machine

- High quality and consistency of the finished product

- High work efficiency

Technical Specifications:

- Hem width: 1.8 – 3.5 cm

- Width of garment pieces: 10 – 80 cm

- Depth of garment pieces: 10 – 100 cm

- Sewing speed: 3,500 stitches/min

- Output: 350 – 480 pieces/hour

- Thread break sensor

- Piece counter

- Power supply: 230V/50Hz

- Operating pressure: 4 bar

- Weight: 400 kg

For proper operation, connection to a compressed air source is required. The machine features a modern energy-saving servo motor that ensures quiet operation and low energy consumption. It is controlled via an easy-to-use and clear control panel.