- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

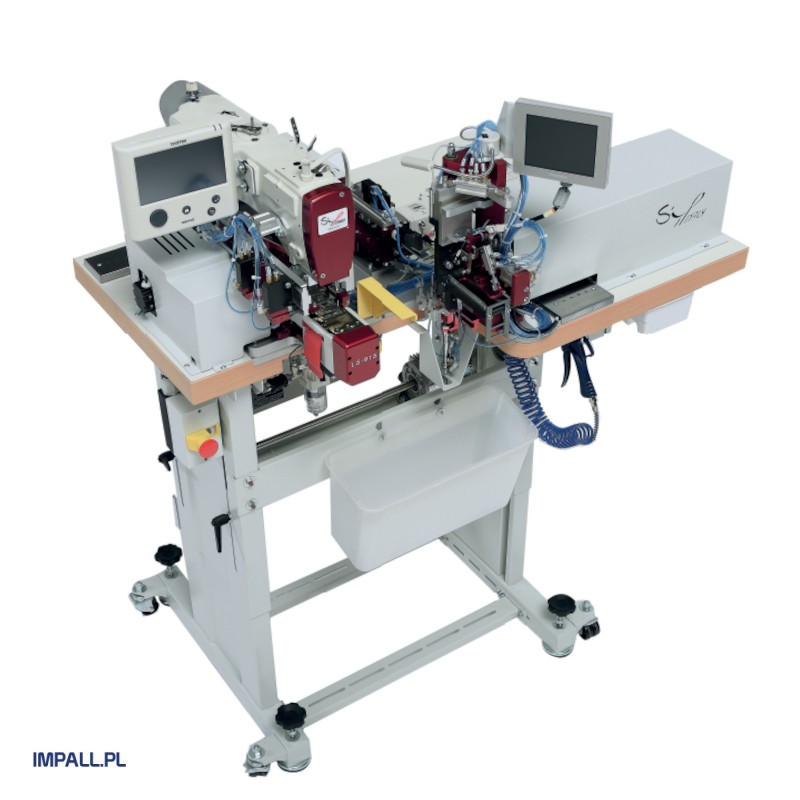

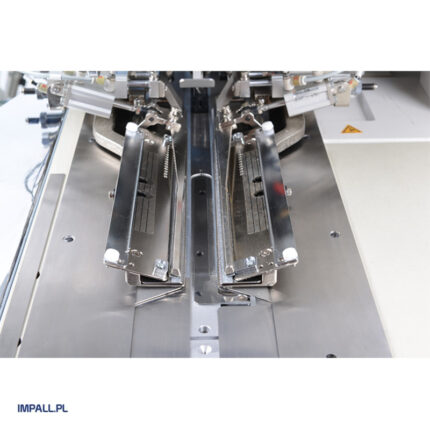

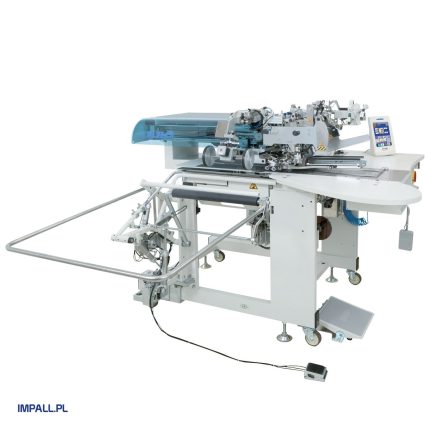

A sewing machine automation system designed for attaching belt loops, equipped with a 2-needle sewing head that allows both tacks on the loop to be sewn simultaneously. Automatic measurement, cutting, folding, and stitching of the loop in one operation significantly improve the machine’s efficiency while ensuring excellent consistency and stitch quality. The machine is controlled via a clear 5.6″ touchscreen panel with self-diagnostic functionality. The operator’s task is limited to placing the garment in the machine’s working area.

Key features:

- Adjustable spacing between the cutter and loop-forming device enables sewing loops with a “buttonhole.”

- The narrow cylinder of the sewing machine allows for loop stitching on small elements (e.g., children’s clothing).

- The machine can also be used for working with elastic materials.

- Possibility of creating decorative tack designs.

- Large workspace between the machine and the feeder.

- Adjustable machine base height.

Technical specifications:

- Sewing speed: up to 2,800 stitches/min

- Productivity: 1,500 – 1,700 pairs of trousers (5 loops per waistband)

- Enlarged capacity hooks

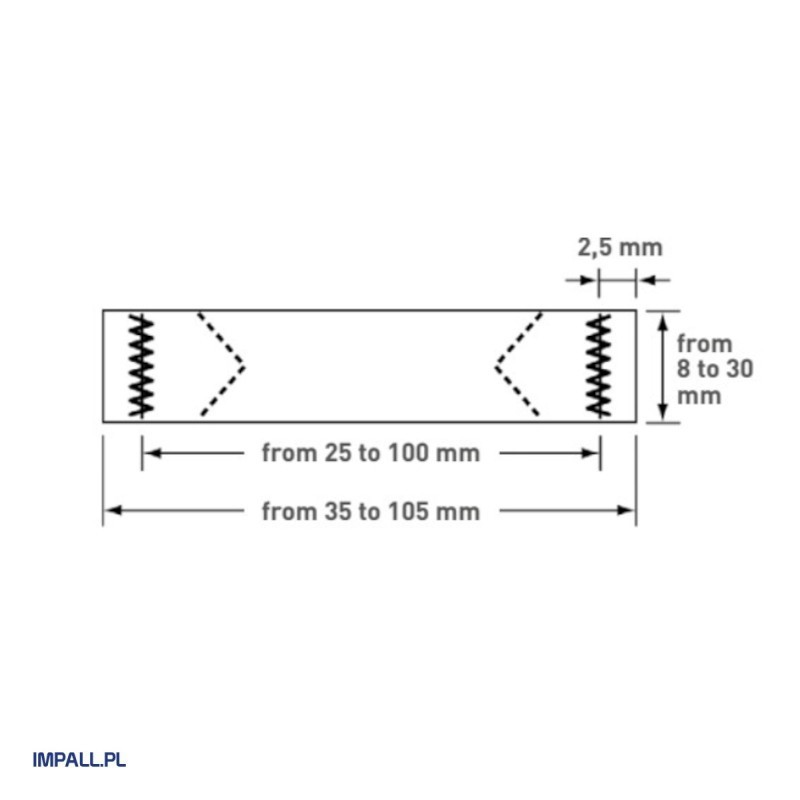

- Loop length: 35 – 105 mm

- Needle spacing: 25 – 100 mm

- Loop width: 8 – 30 mm (30 mm requires special parts)

- Touchscreen control panel

- Straight loop cutting or corner trimming

- Automatic detection and trimming of thick areas (tape joints) on the loop

- Requires connection to compressed air

- Air consumption: 1.5 l/cycle

- Working pressure: 5.5 bar

- Power supply: 230V