- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

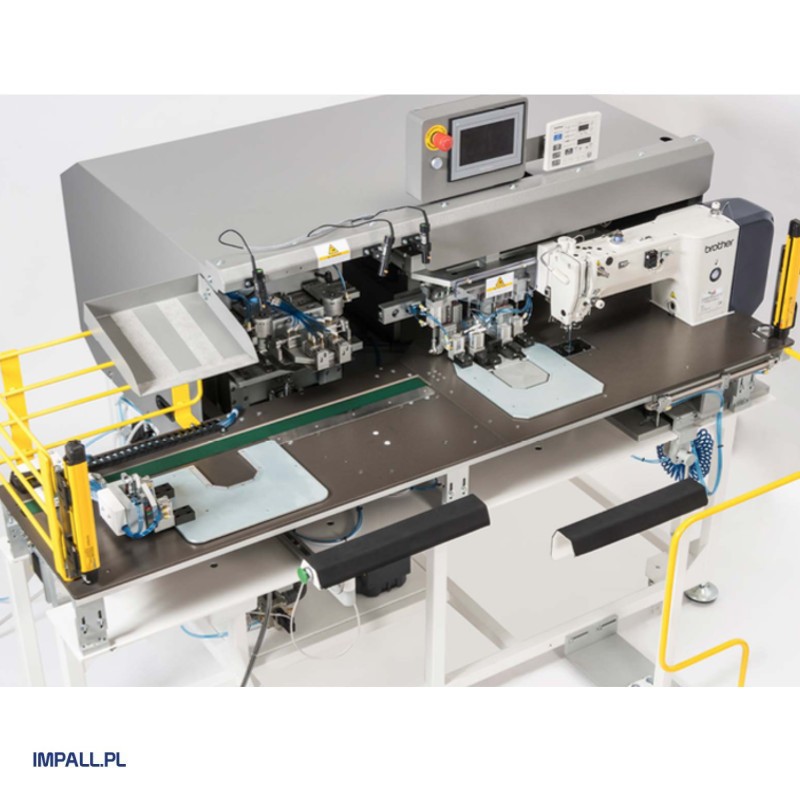

Automatic Pocket Hemming and Stitching Workstation designed for folding and stitching pockets in a single operation, eliminating the need to pre-press pockets. This machine is tailored for high-volume pocket production and is available in different subclasses suited for sewing pockets on knit or woven fabrics.

Specifications and Technical Data:

- Folding and stitching in one operation

- Cold folding process

- No need for skilled labor

- Thread break sensor

- Memory for up to 512 programs

- 7” color screen

- Average operation time: 12 seconds

- Sewing area: from 80x80mm to 250x250mm

- Quick form change

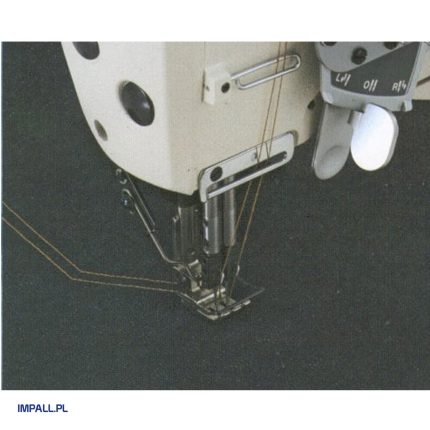

- Sewing head: Bas 311H

- Sewing speed: up to 2500 stitches/min

- Power supply: 230V

- Power: 1200 W

- Air consumption: 8 liters/cycle, pressure 5.5 bar

- Power consumption: 1.0 – 1.2 kW per hour

- Dimensions and weight: 230 x 178 x 150 cm / 450 Kg

The machine features advanced technologies that reduce energy consumption while increasing efficiency:

- All mechanisms are powered by modern energy-saving servo motors or stepper motors (lower energy consumption)

- The pocket-folding form has no heated elements for pressing the edges (lower energy usage)

- Automatic edge folding, feeding under the machine, and stitching per programmed pattern significantly boost productivity compared to manual pocket pressing and stitching, also lowering energy use per pocket produced

- Automation ensures high repeatability and stitching quality

- Quick-change form mechanism enables easy adjustments when changing pocket shapes, minimizing machine downtime

- Laser markers assist with precise pocket positioning on the material