- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

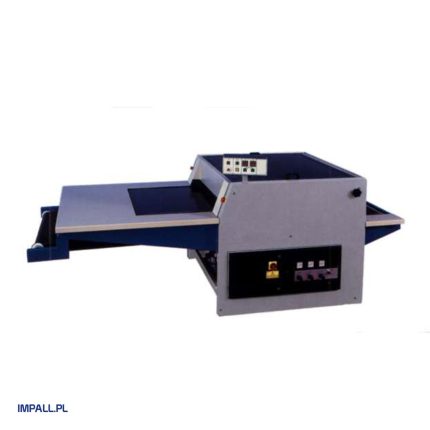

SIP ITALY 1SIP MAXI

AUTOMATIC POCKET PRESSING STATION

Description

Description

Station for Automatic Pressing of Pockets or Pocket Flaps

A station designed for the automatic pressing of pockets or pocket flaps. The device is equipped with two independent heads, allowing simultaneous pressing of two different pockets. Each forming head has its own heating module, enabling separate work parameters to be set for each head. Adjustable pressing time and temperature.

Various pocket shapes can be formed, and changing the form is easy and can be done by the machine operator.

A system for unfolding folded corners ensures the highest quality of the final product after pocket attachment (applicable to pockets with corners).

Technical Specifications:

Working area:

- Width: 60 – 250 mm

- Height: 75 – 250 mm Power: 0.5 kW/h

Operating pressure: 5.5 bar

Power supply: 230V

Air consumption: 9 l/hr

Capacity: 550 pcs/hr (when operated by two people)

Dimensions: 155 x 83 x 128 cm

Weight: 300 kg

Requires connection to compressed air.

Additional information

Additional information

| Brand |

|---|