- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

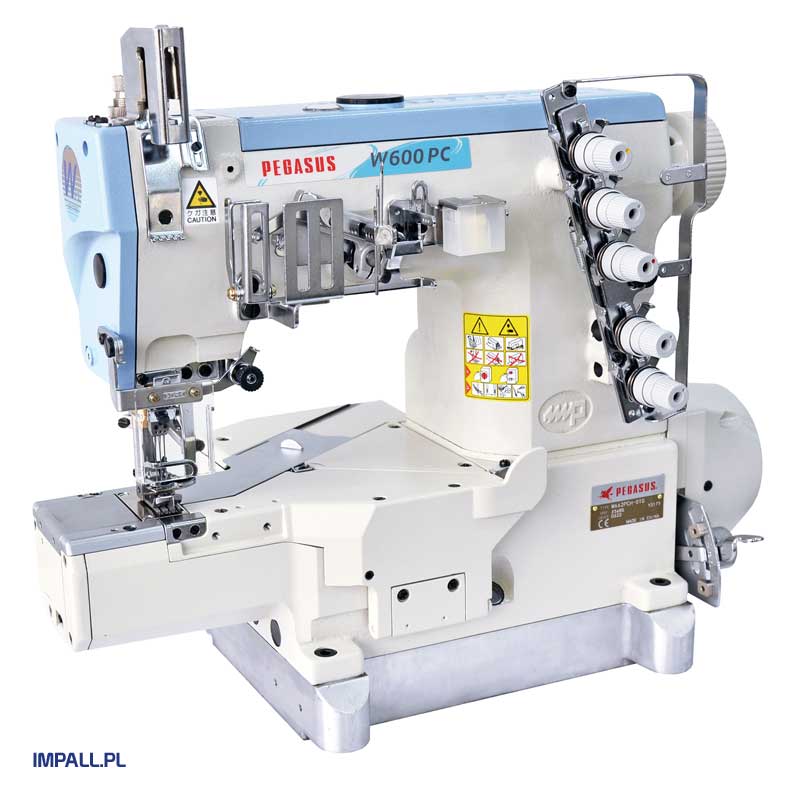

Specialized coverstitch cylinder machine for hemming bottoms of sportswear (such as T-shirts), equipped with a left knife for trimming excess folded material. The machine can perform 2 or 3-needle stitching with or without top coverstitch. Powered by a modern, energy-saving Pegasus D332 servo motor with 650 W, built into the machine head, providing needle positioning and automatic (pneumatically controlled) thread trimming and presser foot lifting.

Technical Specifications:

- Number of needles: 3

- Needle spacing: 5.6 or 6.4 mm – others available on request

- Stitch length: 1.2 – 4.4 mm

- Differential feed: 0.5 – 1.3

- Presser foot lift height: 6.1 mm

- Sewing speed: 5,000 stitches/min

- Needle system: UYx128GAS #10

- Power supply: 230V 50Hz

Connection to compressed air is required. The machine uses advanced “Oil Barrier” technology. The needle bar mechanism is equipped with newly developed oil caps and sleeves that create a unique “oil barrier” preventing oil leaks and staining of products. The “oil barrier” prevents even a single drop of oil from dripping from the needle bar mechanism and its associated parts during machine operation, even when the machine is stopped overnight. Maintenance of the needle bar mechanism is straightforward and only involves replacing the oil cap.

A reliable lubrication system and highly effective “oil barrier” protect the product from oil stains and eliminate the need for stain removers. The W600PC series ensures a clean working environment and helps protect the environment.