- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

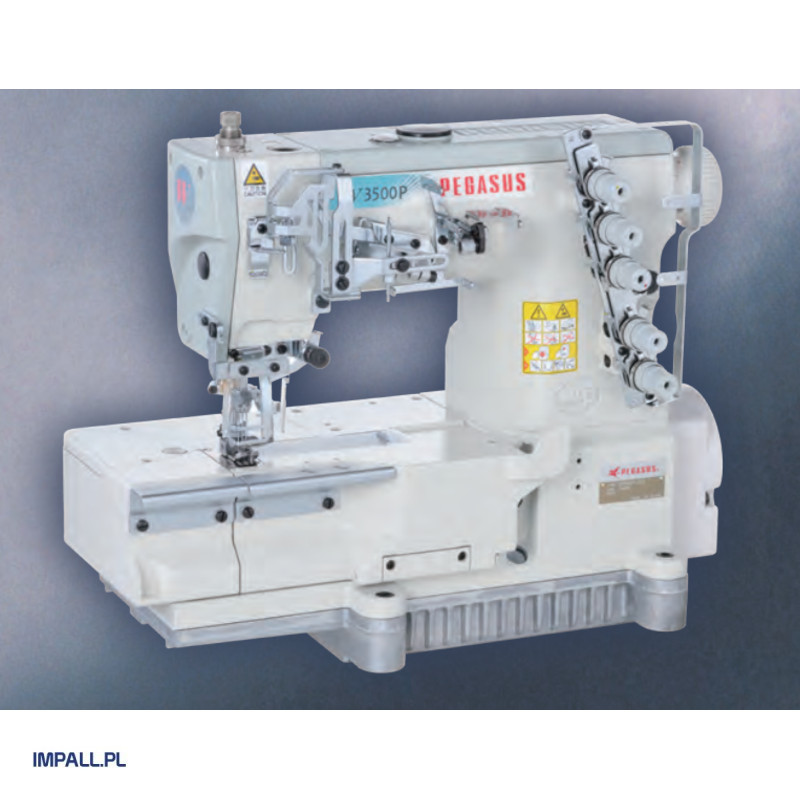

PEGASUS W3562HP-21BX364BS/UT4M/Z054

LADDER MACHINE FOR SEWING THICK KNITTED FABRICS – AUTOMATION

Description

Description

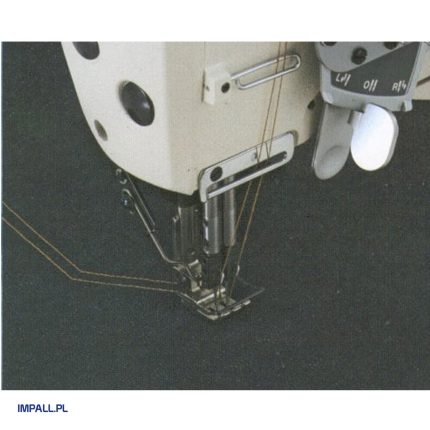

A universal flatbed coverstitch machine designed for sewing thick knits such as fleece, softshell, etc. Two- or three-needle stitching, with or without topstitching. The machine is driven by a modern, energy-efficient servo motor mounted on the machine head, providing needle positioning, automatic (pneumatically controlled) thread trimming, and presser foot lifting.

Technical specifications:

Number of needles: 3

Needle gauge: 5.6 or 6.4 mm

Stitch length: 1.2 – 3.3 mm

Differential feed: 1:0.5 – 1.0

Presser foot lift: 7.4 mm

Sewing speed: 5,000 stitches/min

Power supply: 230V 50Hz

Compressed air connection required. The machines feature modern “Oil Barrier” technology. The needle bar mechanism is equipped with newly developed oil bushings that create a unique “oil barrier” and prevent oil leakage and product staining. This “oil barrier” prevents even a single drop of oil from leaking from the needle bar mechanism and related parts during machine operation, even when the machine is stopped overnight.

A reliable lubrication system and highly effective “oil barrier” protect the product from oil stain contamination and eliminate the need for stain remover. The W600PC series ensures a clean working environment and helps protect the environment.

The machine features a new, retractable looper thread take-up cam mechanism, allowing for much easier access for necessary service.

Additional information

Additional information

| Brand |

|---|