- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

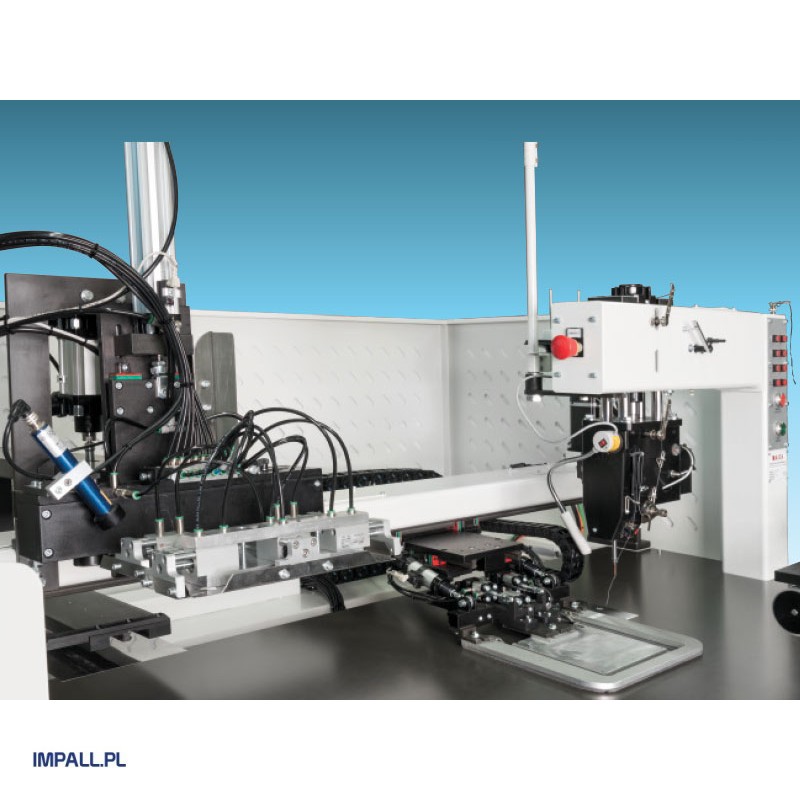

Shirt Pocket Sewing Automatic Machine

A sewing automation machine designed for attaching pockets to shirts, T-shirts, and similar garments. The specially designed sewing head ensures top-quality stitching, while the advanced material folding feeder allows pockets to be sewn on without prior pressing. The machine features laser markers to help accurately position pockets on the fabric. A suction system holds the folded pocket securely on the material, preventing accidental shifting.

There is also an option for sewing pockets with flaps, finishing collar corners, or attaching labels. The machine includes a quick and easy changeover for the forming set. Equipped with intuitive control software, the machine allows users to independently program, save, and modify sewing patterns. Operated via an included computer, it can connect to the internet for remote diagnostics and troubleshooting.

Technical Specifications:

- Sewing speed: 3,500 stitches/min

- Working area: adjustable

- Production capacity: 180–250 pcs/hour

- Power supply: 380V – 50Hz

- Operating pressure: 7 Bar

- Air consumption: 4L per piece

- Weight: 560 Kg

- Requires compressed air connection.