- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

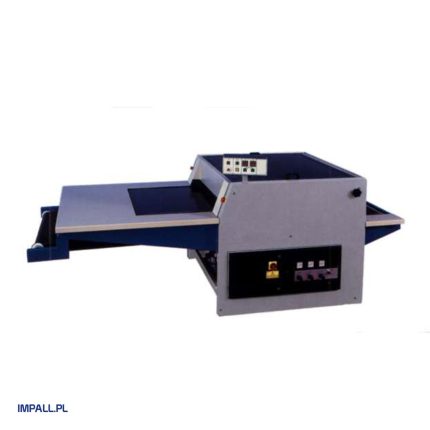

Final collar pressing station. Precise shaping of the finished product and quick, easy template changes ensure the highest quality and productivity. Accurate temperature and time adjustment via PLC controller. Dual pressing — first on the collar shaping form, then a second pressing after the form exits the machine’s work zone. The pressing plates are covered with a special rubber layer to prevent glossing, particularly important for dark fabrics. Adjustable temperature on the upper and lower plates provides even heating on all sides for optimal results.

Technical Specifications:

- Output: approximately 150 items/hour

- Power supply: 230V/50Hz

- Power: 1.2 kW

- Working pressure: 6 Bar

- Air consumption: 5 L/item

- Weight: 170 kg

Requires connection to compressed air.