- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

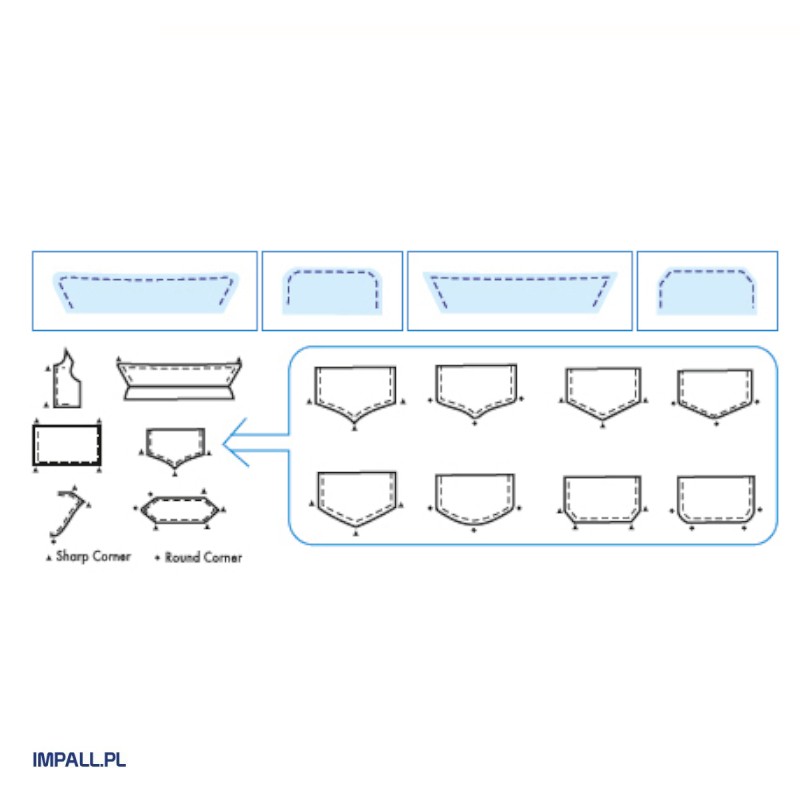

A sewing machine designed for stitching small elements such as collars, cuffs, tabs, epaulettes, front facings in men’s and women’s clothing, and all other stitching operations for elements that need to be turned later. The sewing head is a lockstitch machine (JUKI) with specialized transport and a unique edge cutter. The edge cutter enables effective and precise trimming of the fabric edge when stitching all types of corners, both curved and sharp. Particularly difficult corners are stitched with great precision. During corner stitching, the sewing machine needle stops completely while the template rotates, and the edge cutter continues to work simultaneously. A significant advantage is the ability to sew elements with both outer and inner curves at the same time.

The MJ-3400 is a fully electronically controlled, programmable machine using a digital controller, and important working parameters such as stitching speed on straight sections, stitch length, stitching speed on curves, minimum speed on sharp turns, activation/deactivation of the edge cutter, etc., can be saved as a separate program and recalled from memory at any time for quick execution. The control panel features a large LCD display where the operator can see all the main working parameters in real time. The display is easy to read and understand. For ease of operation, the machine allows the selection of the type of element being sewn from a factory-stored library of several stitching patterns, which can be easily selected. Stitching patterns are displayed graphically.

Technical Specifications:

- Cutting width: 4.8 mm (optional 6.4 mm)

- Sewing speed: 3,000 stitches/min

- Dimensions: 1200 x 780 x 1770 mm

- Weight: 145 kg

- Working air pressure: 5-6 kg/cm²

- Air consumption: 12 l/min

- Power: 1000 W

- Power supply: 230V

Connection to a compressed air source is required.