- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

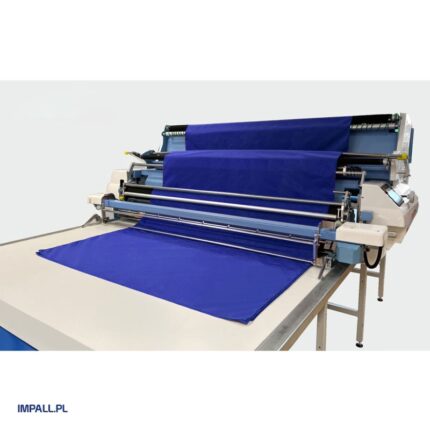

KURIS SK25

COMPACT CUTTER

Description

Description

Compact Multi-Layer Cutter designed for cutting materials up to 25 mm thick when compressed. This compact and versatile device excels in various applications and industries, including furniture manufacturing and other sectors requiring multi-layer cutting. The SK25 combines the benefits of German KURIS engineering with a competitive price, making it an ideal solution for smaller workshops and factories where space for long cutting lines is limited. It is perfect for applications that do not require the high output of conveyorized cutters but demand the precision and quality characteristic of all KURIS cutters. Its modular design allows the cutting area to be extended as needed.

Key Specifications:

- Maximum cutting speed: 40 m/min

- Maximum head speed: 70 m/min

- Cutting area length: 3.4 m

- Cutting area width: 1.6 m

- Total device length: 4.75 m

- Maximum cutting height (compressed): 25 mm

- Power supply: 3-phase 400V 56/60Hz

- Power consumption: 2.5kW + 7.5kW (vacuum)

KURIS Cutter Features:

- Visualized cutting layouts on the computer terminal monitor.

- Easy maintenance with standard spare parts and components for simplified repairs.

- Simple, fast, and convenient blade replacement.

- Rapid positioning of the cutting head ensures optimal blade utilization.

- Control system designed by KURIS guarantees top cutting quality.

- Wide selection and customization of notches.

- Cutting resumes from the exact point after a power outage.

- Automatic self-cleaning of brushes.

- Automatic blade sharpening with high-speed sharpening elements ensures superior blade quality.

- Operator notification for blade wear and replacement.

- Automatic adjustment of cutting speed to shapes and angles improves cutting precision.

- Bottom vacuum system for secure material fixation with high efficiency and low energy consumption.

- Dual-zone knife cooling system, including foot cooling for enhanced performance.

- Vacuum pump can be installed in a separate room (on selected models) to reduce noise and facilitate servicing.

- Table surface with brushes adapted to various cutting window widths.

- Smart Knife technology automatically compensates for blade deflection, ensuring precise cutting of intricate contours and heavy materials (optional).

- Dynamic servo motor-driven system delivers high torque and acceleration, even at low speeds, for fast and accurate frame positioning.

- Proprietary cutter control software.

- High cutting speed for efficient single-layer cutting.

- Economical suction unit with optimized suction force regulation reduces energy consumption.

- User-friendly operator terminal with clear guidance simplifies operation and provides data on current cutting tasks.

- Additional control panel on the machine bridge allows direct bridge operation without accessing the terminal.

Additional information

Additional information

| Brand |

|---|