- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

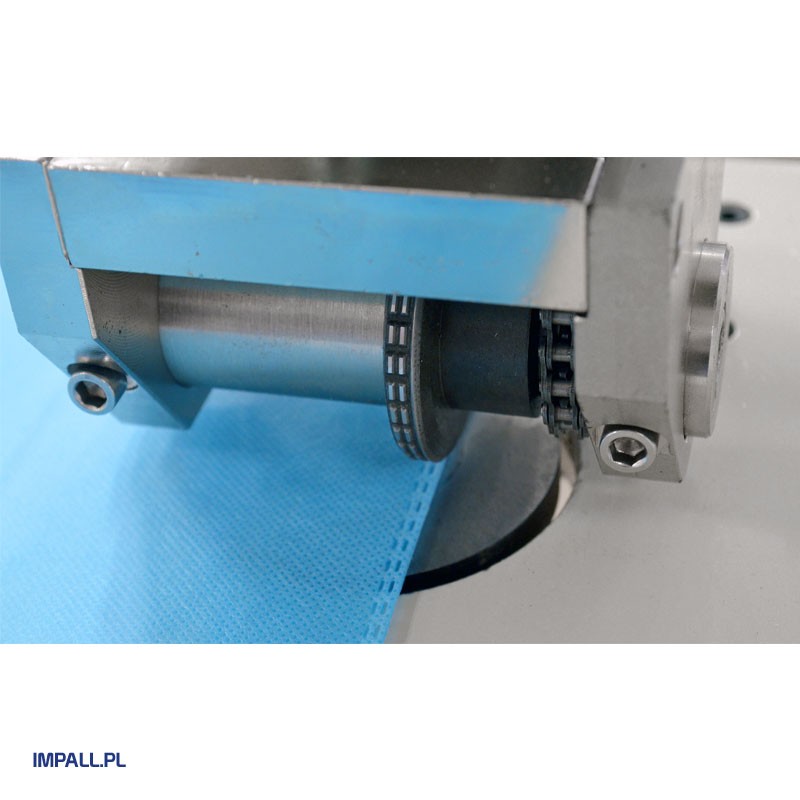

An ultrasonic machine designed for bonding, cutting, or decorative finishing of products such as face masks, disposable medical clothing, protective clothing, as well as technical products, tablecloths, covers, tapes, ribbons, and many more. This effect is achieved by introducing the processed elements into the action zone of special pressure rollers.

The bonding and cutting process is safe, smoke-free, and without the risk of material ignition. Ultrasonic cutting guarantees the highest quality while providing aesthetically pleasing edge finishes.

The machine is standardly equipped with one type of pressure roller, allowing for one type of finishing pattern. Depending on customer needs, a wide range of rollers is available to provide various finishing styles. It can weld and cut both in straight lines and curves.

For proper operation, connection to a compressed air source is required.

Materials must contain at least 70% synthetic fibers.

Technical data:

- Working speed: up to 22 m/min

- Decorative roller width: 68 mm

- Frequency: 20 KHz

- Power: 1500W

- Power supply: 230V