- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

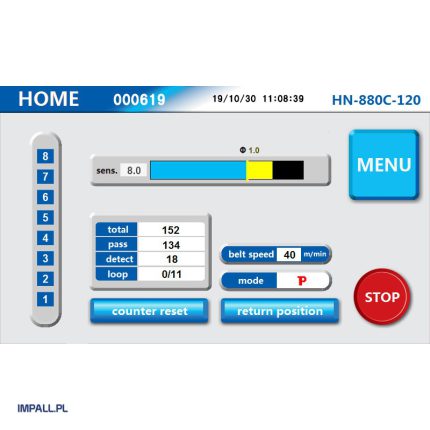

KRAFFT KF-7500ZX

NEEDLE DETECTOR (DESIGNED FOR CARTONS)

Description

Description

Magnetic detector for detecting left-behind metal elements in clothing, toys, footwear, and other textile products. Its high sensitivity allows for the detection of pins, broken needle fragments, staples, and other metal parts that may remain in the product during production.

The KF-7500ZX features the most advanced magnetic detection technology. Detection width: 750mm; detection height: 380mm; max weight: 50kg. It is mainly used for checking entire packages after they are packed to find blades, scissors, as well as small and large metal objects left inside. The KF-7500ZX uses the latest magnetic detection technology and control system. The double row of electromagnetic sensors is mainly used for detecting broken needles and other metal elements in shoes, caps, plush toys, and other small products.

Technical specifications:

- Sensor type: Magnetic induction

- Sensitivity: Fe Φ3.5mm

- Working width: 750mm

- Working height: 380mm

- Belt speed: 30m/min

- Power: 260W

- Dimensions: 1700(L)×1150(W)×1250(H)mm

- Weight: 280kg

Device features:

- Belt anti-skid protection.

- Alarm when a broken needle or metal fragment is detected.

- Automatic idle shutoff function to standby mode.

- Strong resistance to magnetic interference, high reliability, and high sensitivity of the device.

Additional information

Additional information

| Brand | KRAFFT |

|---|

Related products

KRAFFT KF-130LR

In stock