- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

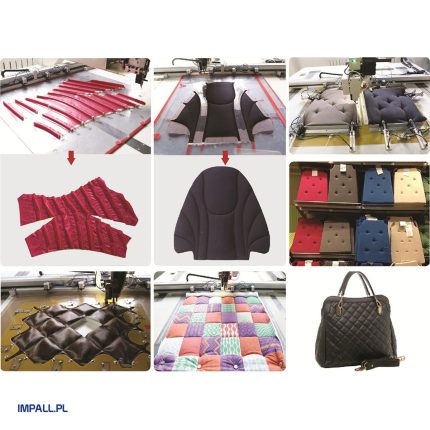

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

KRAFFT KF-254

AUTOMATIC MACHINE FOR SEWING BELT LOOPS

Description

Description

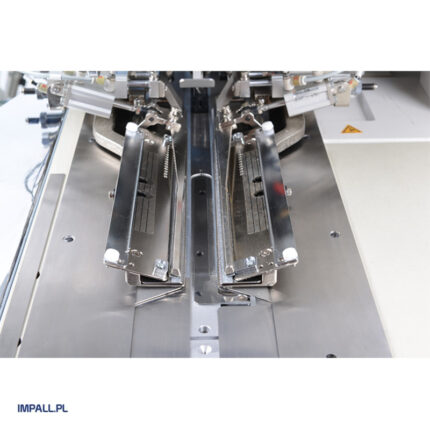

A modern sewing automation machine designed for attaching belt loops on various types of garments. The machine features a specially designed 2-needle head, allowing simultaneous attachment of belt loops with two bar tacks. It includes an automatic belt loop feeder from tape with simultaneous cutting to programmed length and forming the desired hem, significantly reducing the time needed to attach each belt loop. The operator’s role is limited to positioning the garment in the machine’s working area. The machine also allows for securing belt loops with decorative bar tacks.

All machine settings are adjusted via a clear LCD touchscreen control panel. Belt loops can be cut straight or with double-sided diagonal cuts.

Output: 180-200 pairs of pants assuming 5 belt loops per waistband.

Technical Specifications:

- Sewing speed: 2,700 stitches/min

- Bar tack width: 1.0 – 3.5 mm

- Bar tack length: 5 – 22 mm

- Presser foot lift height: 21 mm

- Belt loop tape width: 7 – 20 mm

- Power supply: 230V

- Weight: 245 kg

- Requires compressed air connection at 0.5MPa

- Air consumption: 1.8 l/min

The machine includes a joint detection system for belt loop tape, automatically cutting and discarding any detected joints from the working area.

Additional information

Additional information

| Brand |

|---|