- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

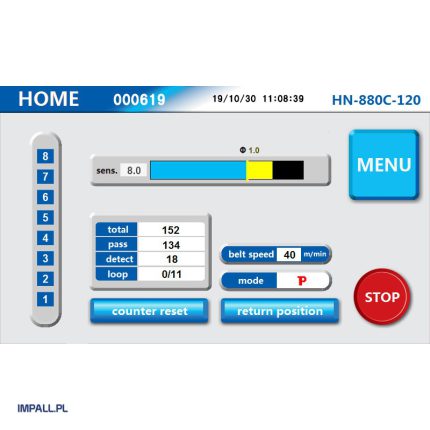

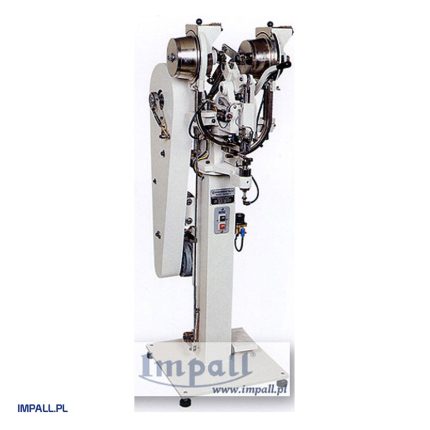

The ultrasonic device is designed for cutting strips or tapes into segments. The machine automatically measures the preset length, which is set on the built-in control panel, and then cuts the programmed number of segments. Cutting is done using ultrasonic technology, simultaneously sealing the cut edge. All data entered into the machine is automatically saved in the device’s memory and protected against loss in case of accidental shutdown. The device can be used for cutting woven tape, plastic cables, plastic zippers, shoelaces, patches, elastic bands, hook-and-loop tape, etc.

This machine is ideal for increasing efficiency, improving product quality, and saving labor. These benefits are achieved through the machine’s high cutting accuracy, speed, and ease of use.

Technical specifications:

- Adjustable cutting length: 50 – 99999 mm

- Maximum cutting width: 150 mm

- Cutting speed: 150 pcs/min for segments of 50 mm length

- Ability to cut multiple tapes simultaneously (parallel)

- Ultrasonic power: 2.6 kW

- Ultrasonic frequency: 20 kHz

- Device power: 3 kW

- Device weight: 178 kg

- Operating air pressure: 4 – 7 bar

- Dimensions: 860×600×1530 mm (L x W x H)

- Power supply: 230V

Connection to a compressed air source is required.