- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

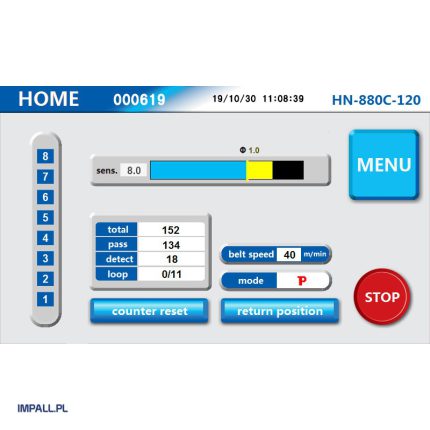

KRAFFT KF-120H

AUTOMATIC TAPE AND VELCRO CUTTING DEVICE (STRAIGHT CUTTING)

Description

Description

The machine can measure a specified length set via the built-in control panel. Increasing the knife temperature with simultaneous edge sealing is crucial for cutting materials prone to fraying. All data entered into the machine is automatically saved in the device memory to prevent loss if powered off. This device can be used for cutting braided tape, plastic tubing, plastic zippers, shoelaces, labels, rubber, Velcro tape, etc.

This is an ideal machine for enhancing efficiency and improving product quality while saving labor. This is achieved through the machine’s high precision, cutting speed, and easy control interface.

Technical specifications:

- Maximum temperature: 400°C

- Cutting length adjustment: 15 – 9999 mm

- Material feed speed adjustment (average output: 70 pcs/min)

- Ability to cut two tapes simultaneously (parallel)

- Power: 0.28 kW

- Power supply: 230V

Additional information

Additional information

| Brand |

|---|