- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

A 4-thread overlock with automatic functions designed for sewing light and medium materials. It features differential bottom feed. The machine is equipped with automatic chain/tape trimming controlled by photocells, a chain and fabric scrap suction system, and automatic presser foot lifting.

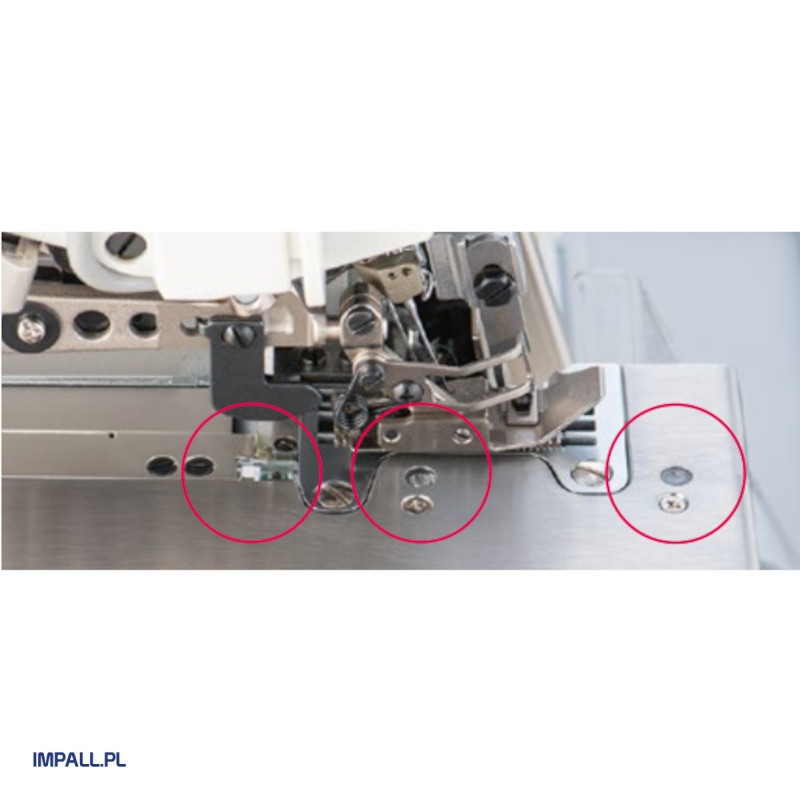

The machine can operate in automatic mode (trimming controlled by photocells), manual mode (trimming activated by a button), or in mixed modes (e.g., the entire sewing process controlled by photocells). The photocells, hidden in the needle plate, are highly accurate and do not limit access to the machine’s working area.

The machine is equipped with an easy-to-read integrated control panel where all parameters related to automatic functions are set. The energy-efficient servo motor is mounted directly on the machine head, directly on the main shaft, ensuring quiet operation and reduced energy consumption.

The integrated LED work area lighting features adjustable brightness and color temperature (cold, warm, or mixed light).

Technical specifications:

- Sewing speed: 7,000 stitches/min

- Needle spacing: 2 mm

- Seam width: 3 mm (total stitch width 5 mm)

- Presser foot lift height: 5.5 mm

- Differential feed: 0.7 – 2.0

- Stitch length: up to 3.6 mm

- Power supply: 230V

The machine comes complete with a table. Connection to compressed air is required.

Servo motors are currently the most modern type of drive for sewing machines. Machines with such a drive consume up to 75% less electricity compared to traditional clutch motors, are quieter, and have less vibration during operation.