- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

JEUX SF-829

SEAMLESS HEMMING AND JOINING MACHINE WITH ULTRASONIC MATERIAL TRIMMER

Description

Description

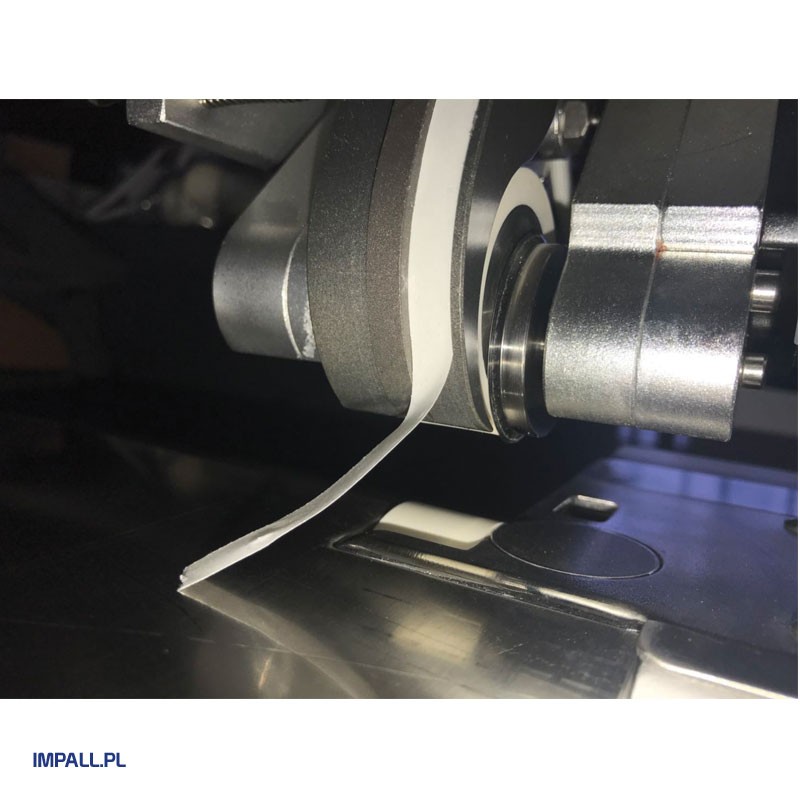

Device for Seamless Tape Application on Fabric Edges using point heating of the tape. This operation is essential as the first step for seamless hemming of materials and for joining two materials with an “overlap.” With its built-in ultrasonic cutter, the tape is precisely aligned with the fabric edge, allowing this edge to be folded (using a dedicated folder) or layered with another material to achieve a flat, seamless join. The ultrasonic cutter ensures a clean fabric edge, eliminating the risk of fraying during trimming.

The machine includes a differential drive (with different speeds for the upper and lower rollers), enabling precise tape application even on curves and challenging materials. Both the tape heating temperature and the feeding and cutting speed are set via a clear, color display. The machine’s housing allows for the installation of various types of tape feeders and folders. This technology is compatible with synthetic fabrics and cotton.

Technical Specifications:

- Power Supply: AC 220V

- Frequency: 28kHz

- Heater Power: 700W

- Max Speed: 5 m/min

- Max Temperature: 350°C

- Max Roller Width: 15 mm

- Dimensions: 1220 x 750 x 1400 mm

- Weight: 140 kg

Additional information

Additional information

| Brand |

|---|