- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

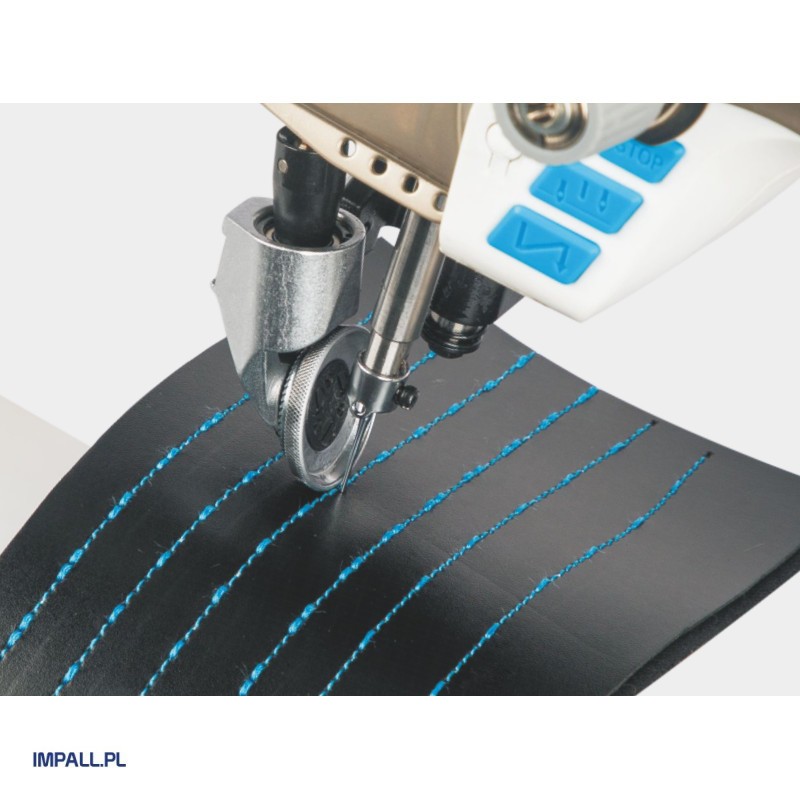

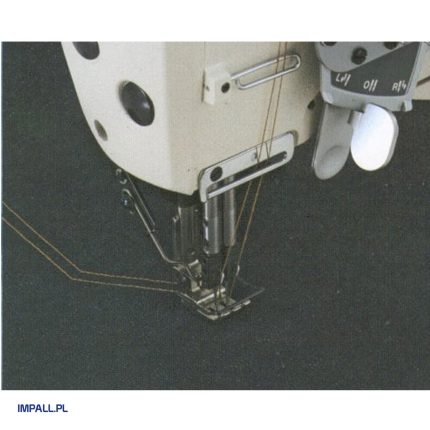

A single-needle post-bed machine with electronically controlled bottom roller feed, needle feed, and roller foot (rolfus). Equipped with three independent stepper motors controlling the feed (top roller, bottom roller, and needle feed), automatic functions, and 3-level energy-efficient LED workspace lighting with adjustable light color. Ideal for sewing medium and heavy materials.

The use of stepper motors for feed control allows the programming of decorative stitches.

Designed for sewing in hard-to-reach areas in the production of sports shoes, leather shoes, leather goods, etc. Thanks to the integration of all components, the machine operates quietly and without adverse vibrations. The modern servo motor consumes up to 70% less energy than a conventional electronic or clutch motor. All sewing parameters can be programmed via an easy-to-read control panel with a built-in USB port for connecting external devices.

The machine is factory-equipped with a drop-down guide (ruler) for precise edge stitching.

Automatic functions:

- Electromagnetic thread trimming

- Electromagnetic foot lifting

- Needle positioning

- Backtacking at the start and end of sewing

Technical specifications:

- For sewing medium and heavy materials

- Triple feed: bottom roller, needle feed, and roller foot (rolfus)

- Maximum stitch length: 5.0 mm

- Foot lift height up to 7 mm (12 mm with knee lifter)

- Maximum sewing speed: 2,500 stitches/min (factory set to 2,200 stitches/min)

- 3-level LED workspace lighting

- Four function buttons next to the needle bar for quick access to frequently used functions

- Needle system: DPx5

- Voltage: 220-240V

- Central lubrication system