- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

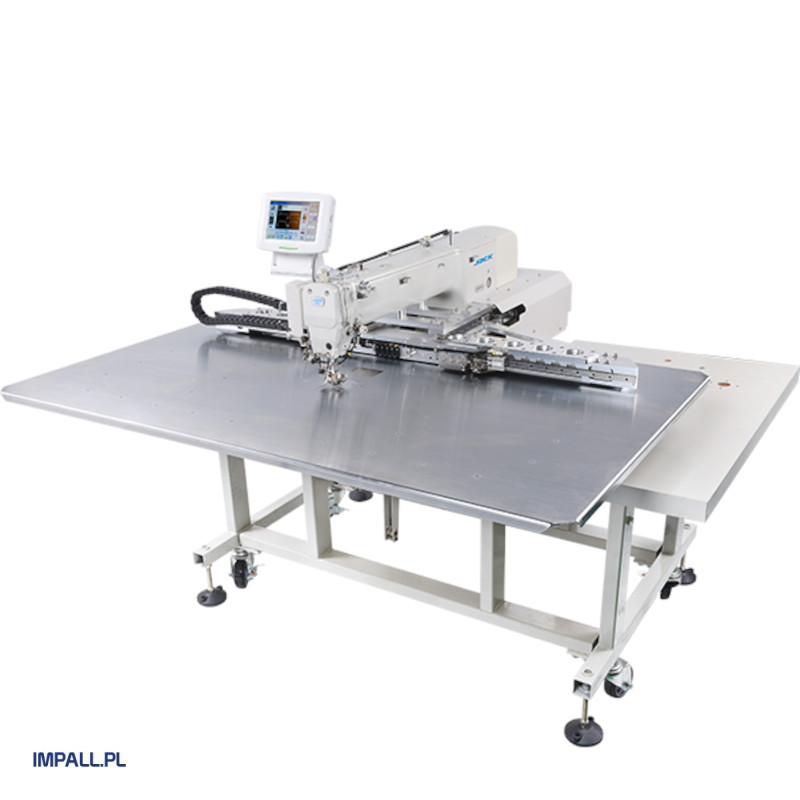

JACK JK-T6040

ELECTRONICALLY CONTROLLED AUTOMATIC SEWING MACHINE FOR PROGRAMMED PATTERNS – SEWING AREA: 600 X 400 MM

Description

Description

Electronically Controlled JACK JK-T6040 Automatic Sewing Machine for Large Elements with 600×400 mm Sewing Area

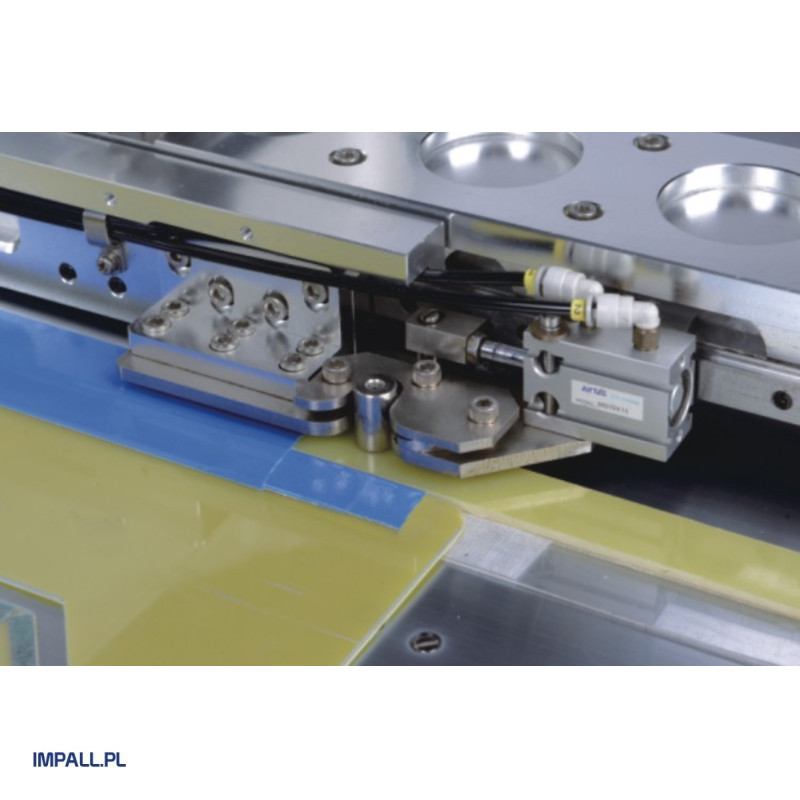

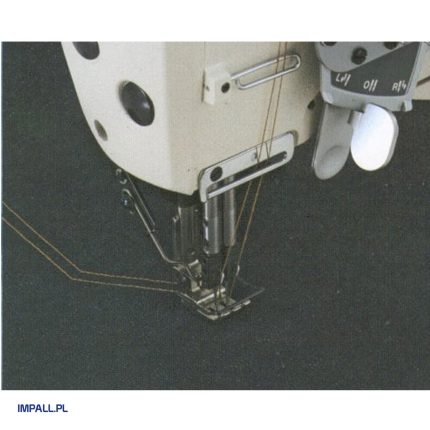

This machine is used for repeatedly executing decorative stitching patterns, attaching labels, Velcro, emblems, as well as sewing pockets, flaps, zippers, and other components. It is also suitable for the production of quilted jackets, coats, duvets, or mattresses. It is ideal for sewing multiple bartacks when attaching straps in the MOLLE system. The machine features a servo motor integrated into the head (Direct Drive system) and stepper motors. It is suitable for various materials and operations, is simple to use, and does not require the operator to have special skills due to its advanced solutions.

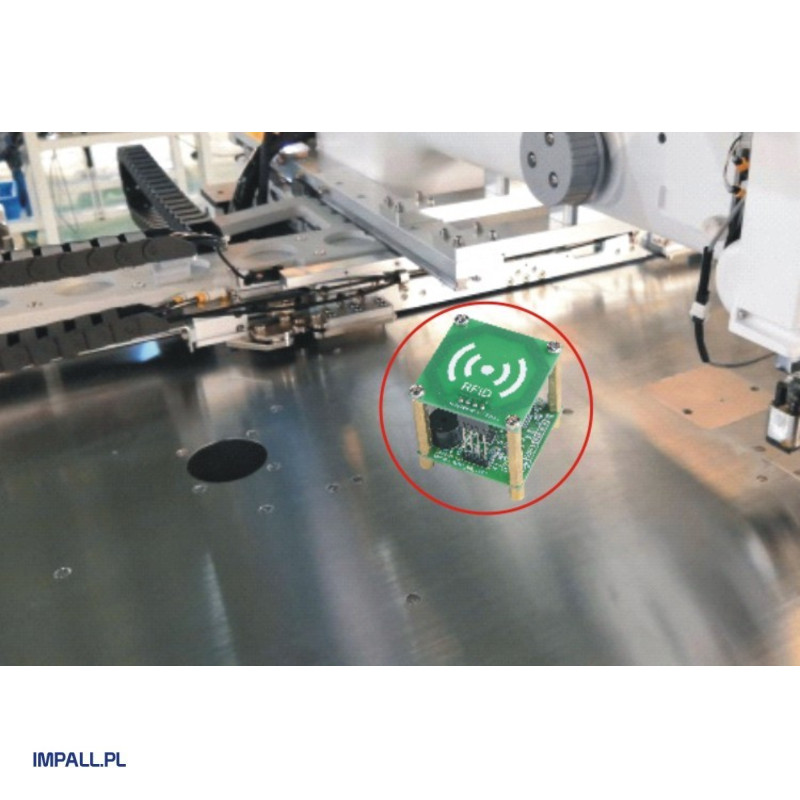

An RFID reader located under the table allows for quick automatic pattern loading based on the type of sewing form used (forms are custom-made and not included as standard equipment).

All sewing parameters can be programmed on a clear, touch-operational panel. Created patterns can be saved in the machine’s internal memory (capacity for 999 patterns) or on external USB memory.

The machine requires connection to a compressed air source (compressor).

Technical Specifications:

- Sewing speed: up to 2500 stitches/min

- Presser foot lift height: up to 22 mm

- Needles: CPx17

- Power supply: 230V

Additional information

Additional information

| Brand |

|---|