- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

JACK JK-T3020-F4-D

ELECTRONICALLY CONTROLLED SEWING MACHINE FOR PROGRAMMED PATTERNS – SEWING FIELD: 300 X 200 MM WITH SLIDING CLAMP

Description

Description

Electronically Controlled Sewing Machine JACK JK-T3020-F4-D for Pattern Sewing

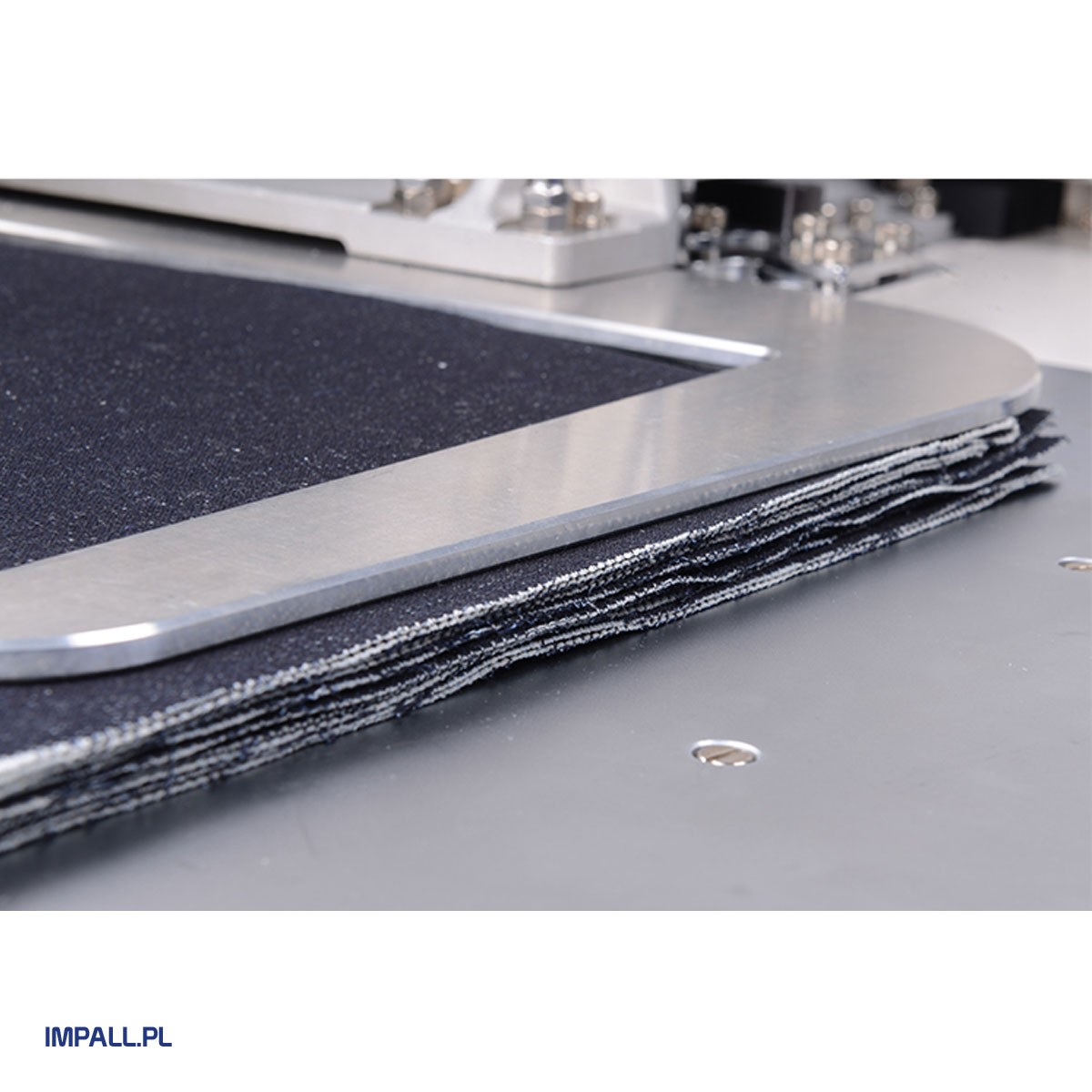

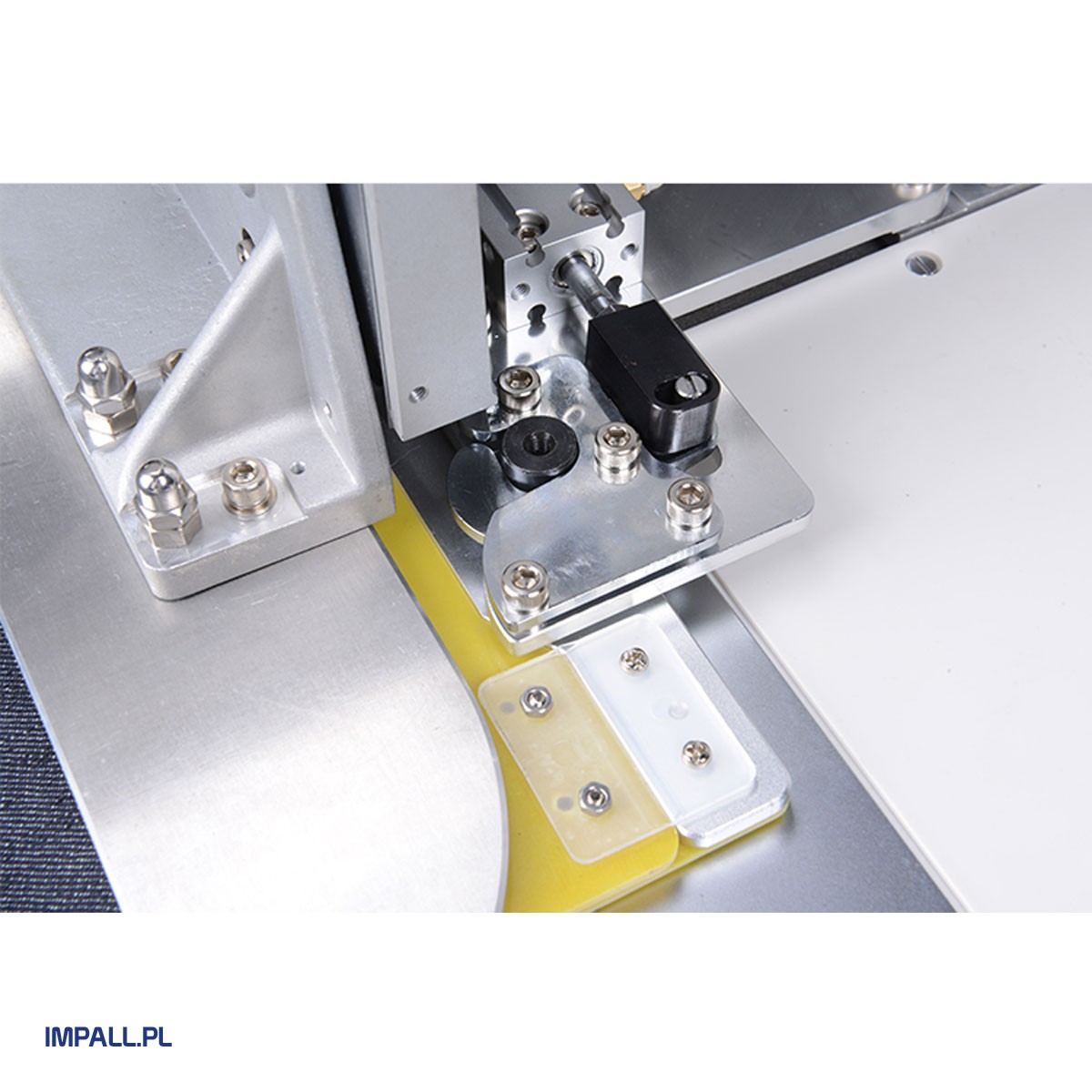

The JACK JK-T3020-F4-D is an advanced electronically controlled machine designed for sewing programmed patterns within a 300×200 mm sewing field. Equipped with a sliding clamp, this machine is ideal for repetitive operations such as attaching labels, sewing Velcro, securing reinforcements, decorative stitching, and more. Powered by an energy-efficient servo motor integrated into the machine head (Direct Drive system), the machine uses stepper motors to control the transport mechanism, ensuring exceptional stitch quality, smooth operation, high precision, and quick start and stop times.

With programmable automatic functions, the machine eliminates the need for operator sewing skills while delivering high consistency and productivity. All operating parameters and stitch patterns are programmed via an intuitive touchscreen control panel.

The F4 version includes accessories for the sliding clamp and a standard split frame, enabling full utilization of the 300 x 200 mm sewing field.

Technical Specifications:

- Sewing speed: up to 2700 stitches per minute

- Internal presser foot

- Presser foot lift height: 22 mm

- Needle system: DPx17

- Power supply: 230V

Note: Connection to a compressed air source is required.

Additional information

Additional information

| Brand |

|---|