- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

JACK JK-58420

TWO-NEEDLE LOCKSTITCH MACHINE

Description

Description

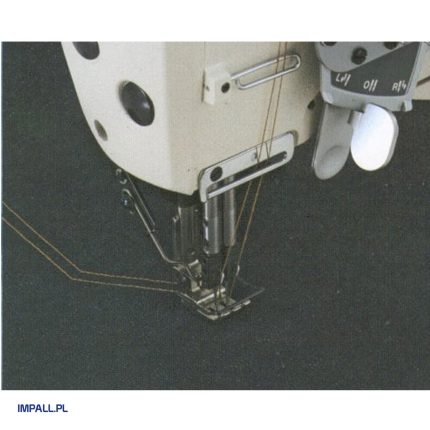

The JACK JK-58420 lockstitch machine is a highly modern two-needle sewing machine utilizing dual needle and feed dog transport. Depending on the selected subclass, the machine is suitable for working with lightweight and medium materials (subclass 403) as well as heavy materials (subclass 405). The JACK JK-58420 industrial sewing machine features a highly intuitive control panel that allows for setting sewing parameters. Through this panel, users can manage the machine’s automatic functions, including needle positioning, thread trimming, presser foot lifting (7-13 mm), and bar tacking at the beginning and end of the stitch.

The two-needle machine comes equipped with an energy-efficient servo motor that operates only when the machine is in use, ensuring reduced power consumption. Additionally, thanks to the Direct Drive system, which places the motor directly in the machine head, the device is more reliable. The elimination of a drive belt reduces unwanted vibrations and noise, enhancing the machine’s performance. This design also provides more power, faster start times, and quieter operation, significantly improving the user experience.

Like other two-needle lockstitch machines in the JACK JK-58** series, the JACK JK-58420 offers a large working area measuring 115 mm x 255 mm (height x width). This space is effectively illuminated by two rows of energy-efficient LED lights, reducing eye strain during sewing and improving precision.

This two-needle lockstitch machine sews at a speed of 4000 stitches per minute. The stitch length varies depending on the subclass. In the regular subclass (for lightweight and medium materials – 403), the stitch length is 4 millimeters. In subclass 405, designed for heavy sewing, the machine allows for a stitch length of 5 millimeters. The presser foot lift ranges from 7 to 13 millimeters, and the standard needle gauge is 6.4 mm, with other sizes available upon request. The needle system used in this machine is DPx5, compatible with needles size 11-16#.

Additional information

Additional information

| Brand |

|---|