- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

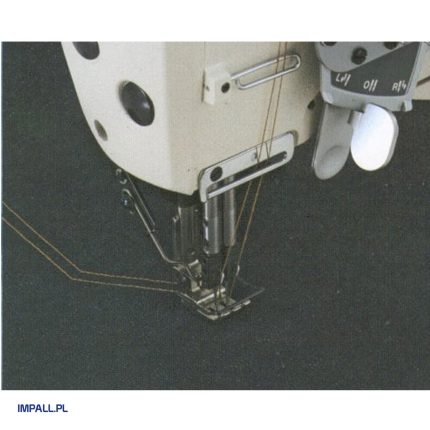

Specialized automatic lockstitch machine with needle and feed dog transport and an extended working area. The distance between the machine body and the needle bar is 30 cm. The dual feed system supports the smooth feeding of materials under the presser foot. The machine is equipped with an energy-efficient servo motor integrated into the head, ensuring quiet and reliable operation as well as reduced energy consumption. Most importantly, the JACK A6F-E lockstitch machine features a closed lubrication system (without the typical oil pan), which guarantees lower oil consumption, better lubrication of the machine mechanisms, and protects the fabric from contamination.

The machine also has integrated LED workspace lighting and a built-in USB port for connecting external devices (such as charging a mobile phone or powering a fan).

Additionally, the E-series machines use a stepper motor to control the stitch length and the bartacking mechanism. This design significantly reduces noise levels when sewing bartacks and allows for very precise stitch length adjustment with an accuracy of 0.1 mm. The machine is also available in a heavy-duty subclass, A6F-EH, for thicker materials.

Automatic functions:

- Thread trimming

- Needle positioning

- Initial and final bartacking

- Presser foot lifting

Technical specifications:

- Sewing speed: up to 4,000 stitches/min (A6F-H up to 3,500 stitches/min)

- Stitch length: up to 4.5 mm

- Presser foot lift height: 5-13 mm

- Built-in LED lighting

- USB port for data transfer and connecting external devices

- Needle system: DBx1 (A6F-H: DPx5)

- Power supply: 230V