- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

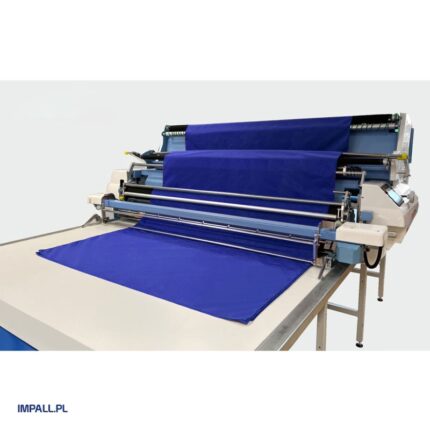

HOFFMAN HF-100P

ROTARY BLADE CUTTER

Description

Description

The HF-100 disc cutters are designed to work with any type of material (from light to heavy). They can cut thin layers of material (2-3 layers) as well as cut high fabric stacks into pieces. All machines are equipped with modern sharpeners, whose unique design allows them to be used directly during the machine’s operation. For the user’s convenience and safety, the cutters can also be equipped with an overhead arm to prevent the cord from being cut!

The HF-100/HF-125 disc cutters are several times lighter than similar devices with the same cutting thickness. Additionally, the small blade diameter ensures the smallest error when cutting individual layers along curves, compared to all known cutters. The HF-100/HF-125 disc cutters have the highest blade utilization rate in their class, reaching up to 90% in some models. This means that the blade diameter is directly proportional to the cutting height.

The HF-100/HF-125 disc cutters feature solutions that are uncommon in this type of machine, even among well-known global brands. One such solution is the use of a voltage drop switch. This modification prevents the machine from turning on automatically after a power outage in the electrical network. This solution has been patented by us. Devices without this type of switch do not meet European Union safety standards.

The modern and unique solutions implemented in the P SERIES cutters allow for smooth adjustment of the cutting disc speed, ranging from 500 rpm to 1000 rpm. This makes it possible to work with practically any type of material using a single device—from silk to denim. The cutting disc speed is adjusted using a potentiometer, which is a modern electronic modification. This is a unique solution for those working with various types of materials, ensuring time and cost savings.

Technical specifications

| Blade diameter | 96 mm |

|---|---|

| Maximum cutting thickness | 85 mm |

| Power supply | 230 V / 50 Hz |

| Motor power | 0.38 kW |

| Net weight | 3.5 kg |

| Gross weight | 4.00 kg |

| Speed | 500 – 1000 rpm |

Additional information

Additional information

| Brand |

|---|