- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

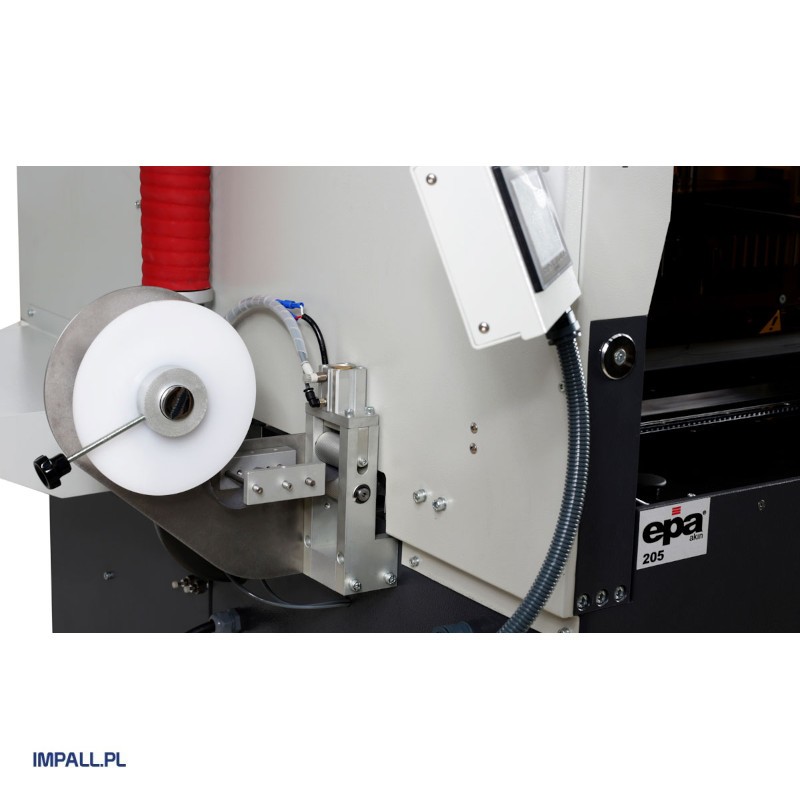

Automatic Shirt Placket Forming Machine

- Capable of pressing shirt plackets with widths ranging from 15 mm to 75 mm

- Can press and form plackets in short-sleeve shirts

- Allows creating various placket designs for shirts and blouses

- Optionally equipped with a system for feeding and cutting the reinforcing tape for the placket

- Specially designed layout table

- Linear laser marker for easy alignment of striped or checkered fabrics

- Oil-free system prevents accidental fabric staining

- Built-in vacuum pump creating suction and forming the material

- Clear and user-friendly control panel equipped with a touch display

- Screen provides hourly and daily production reports

- Intelligent error notification system for easy troubleshooting during machine operation

- Automatic stacking system for finished elements after pressing

- Precise temperature control system ensures energy-saving and accurate heating regulation

- PLC controller system

- Safety features provide secure and safe operation for the operator

Technical Specifications:

- Dimensions: 1400 x 1400 x 1550 mm

- Weight: 560 kg

- Output: 360 pieces/hour

- Required compressed air: 6 bar

- Air consumption: 120 l/min

- Power supply: 380V