- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

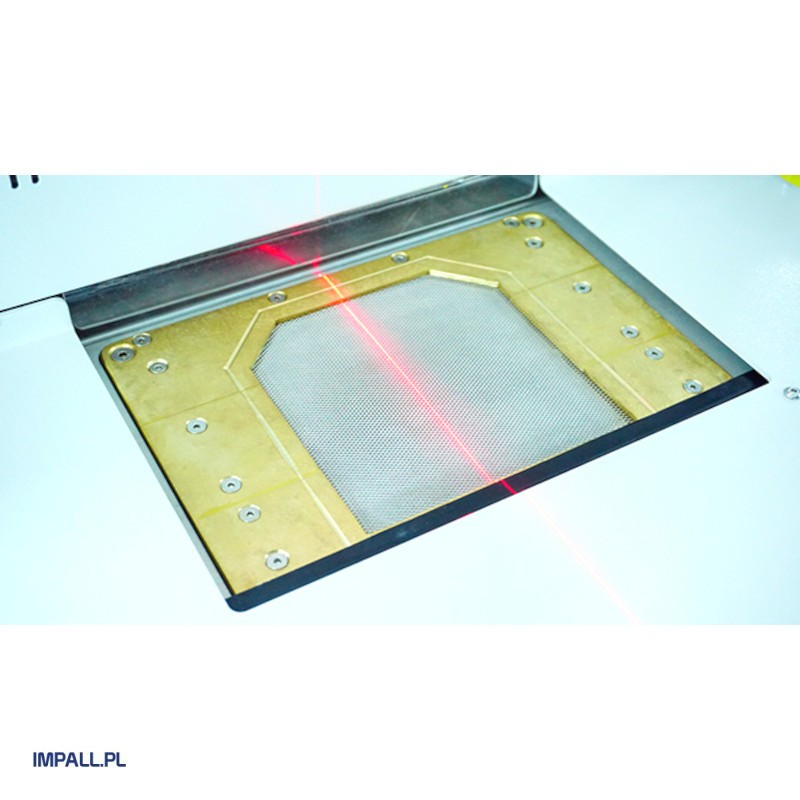

High-performance machine for pressing the edges of pockets, patches, flaps, and other garment components. The use of an automatic system for receiving pressed pieces significantly enhances productivity. The device is controlled via a touchscreen panel with a Polish-language menu.

Technical specifications:

- Power: 7 kW

- Power supply: 380V

- Efficiency: 300 pcs/hour

- Working pressure: 6 bar

- Air consumption: 47 l/min

- Weight: 265 kg

- Dimensions: 950 x 1030 x 1450 mm

Key features:

- Easy change of pressing molds

- Capable of pressing elements from all four sides, enabling the pressing of patches and labels

- Ability to press elements with rounded shapes

- User-friendly touchscreen control panel with a Polish-language menu

- Laser indicator for accurate positioning of elements with checks, stripes, etc.

- High efficiency of up to 300 pieces per hour

- Automatic stacking system for receiving and stacking pressed elements

- Precise and highly accurate temperature control

- PLC control system

- Self-diagnosis system that displays errors if the machine detects any issues