- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

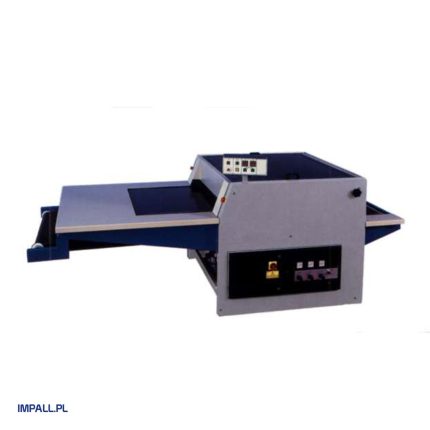

Device for Automatic Sleeve Pleat Formation in Shirts (so-called “House Pleats”)

- Allows for various shapes and sizes of pleats (changing forms is required – optional)

- The machine does not use oil-lubricated mechanisms, eliminating the possibility of staining materials

- Easy-to-use control panel with hourly and daily productivity reporting

- Intelligent system for notifying of any device errors

- Laser markers to facilitate precise alignment of materials in the work area (especially important when working with plaid fabrics to match the pattern)

- Simultaneous pressing of left and right pleats

- Automatic system for transferring pressed pleats to the receiving area

Technical Specifications:

- Dimensions: 950 x 1030 x 1450 mm

- Weight: 265 kg

- Power supply: 380V

- Power: 7 kW

- Capacity: 360 pcs/hour

- Working pressure: 6 bar

- Air consumption: 47 l/min

- PLC control

- Connection to compressed air is required