- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

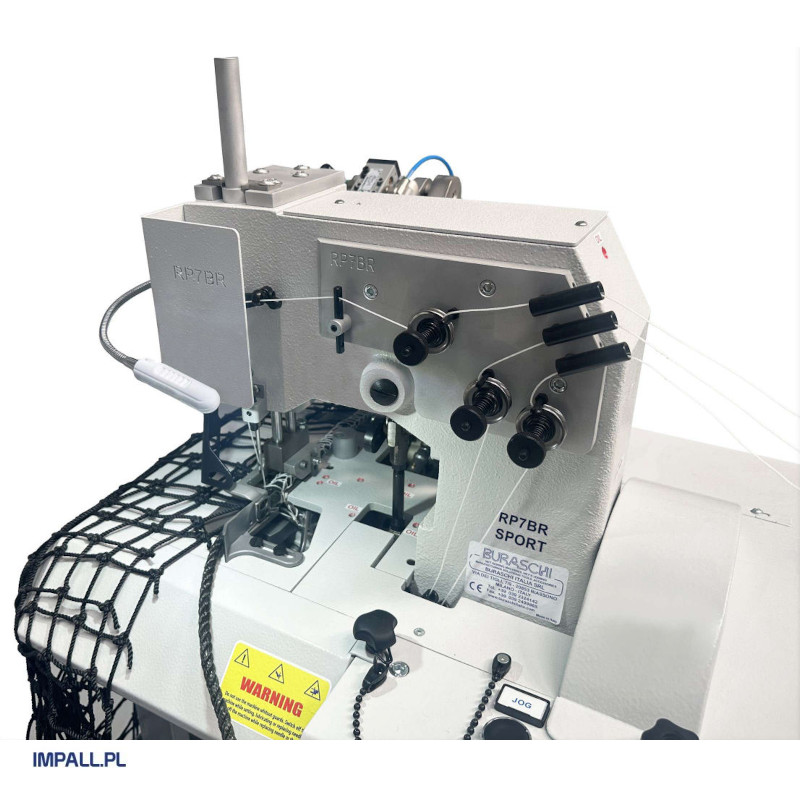

A high-performance sewing station designed for sewing nets, connecting, or adding reinforcing ropes. The machine is suitable for sewing thin and medium-sized nets, both woven and knotted, most commonly used for sports nets, sports field covers, gardening covers, and more. The maximum thickness of the sewn elements is 20 mm.

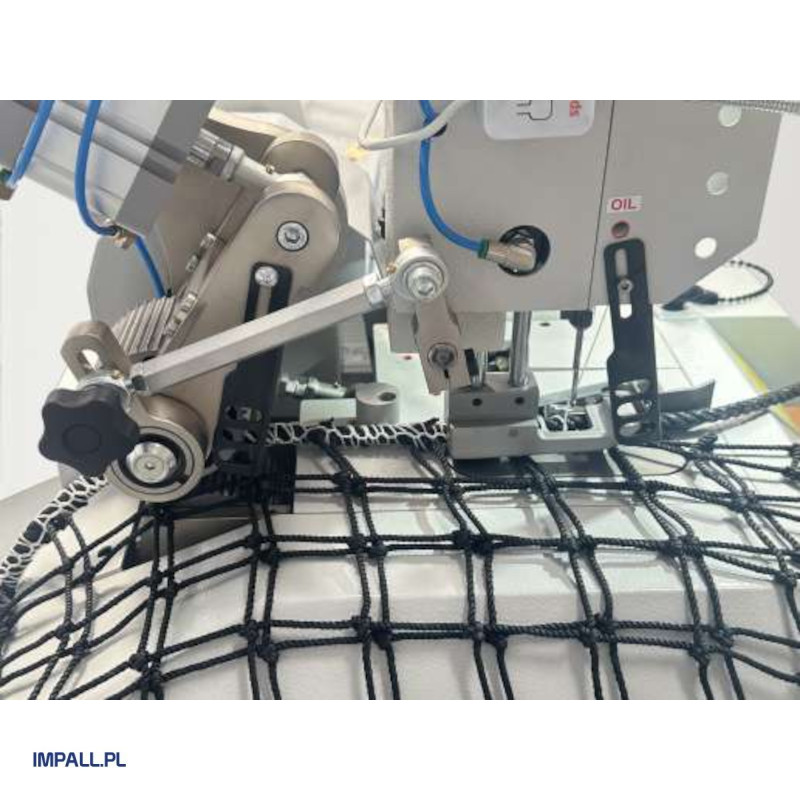

The machine’s needle plate is flush with the table, providing a better ergonomic position for the operator and minimizing the risk of the net catching on the table edges.

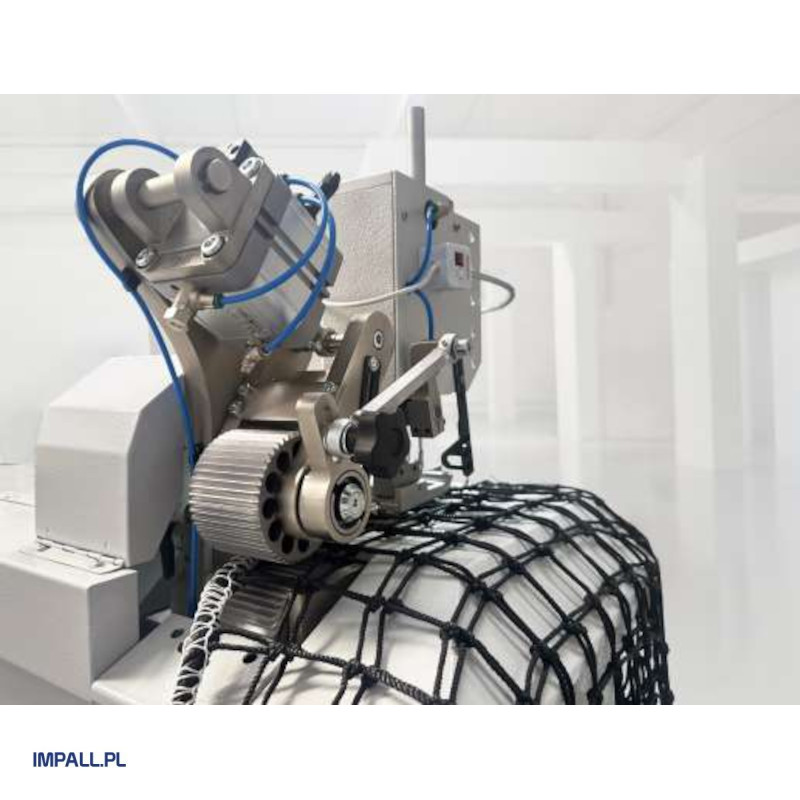

The highly stable and robust construction ensures high durability and allows for efficient and trouble-free operation.

A pneumatic presser foot ensures constant, even pressure on the sewn elements.

A pneumatic metal puller ensures precise material transport (driven by the lower and upper puller rollers).

The use of a special needle with blunt tips prevents damage to the net fibers during sewing. The machine’s components are manufactured using the finest AISI 315 steel alloy, additionally hardened at all critical points.

Technical specifications:

– stitch length 8-15 mm

– sewing speed up to 700 stitches/min

– 400 BUR needle

– 230V power supply

– 1200W power

– machine weight 178 kg

– machine dimensions: height 133 x 60 x 122 cm (width x height x length)

Energy-efficient motor. LED workspace lighting.

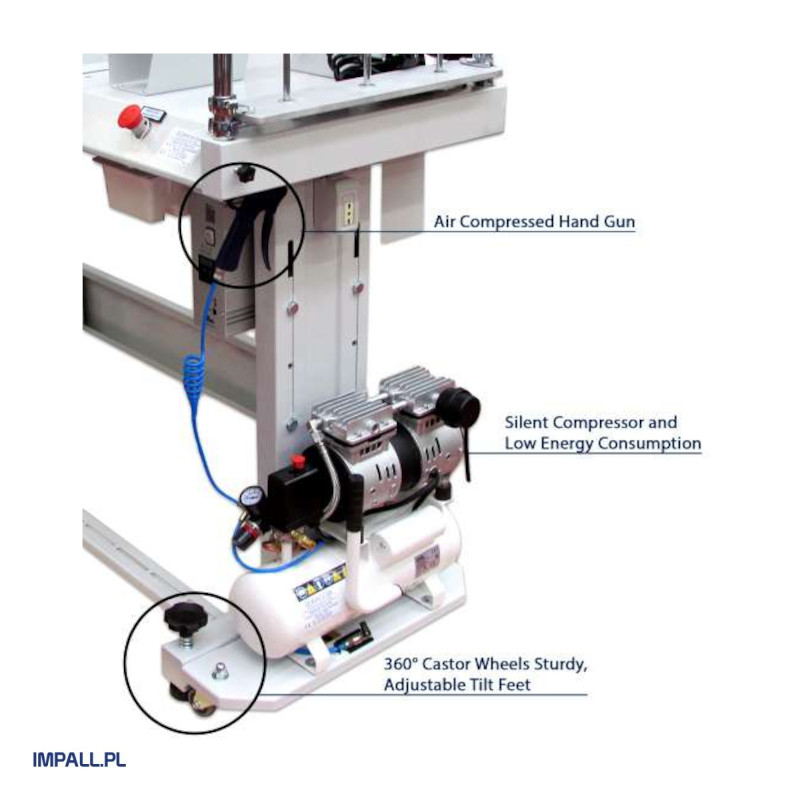

The machine has an integrated, quiet air compressor, eliminating the need to connect to a pneumatic system.