- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

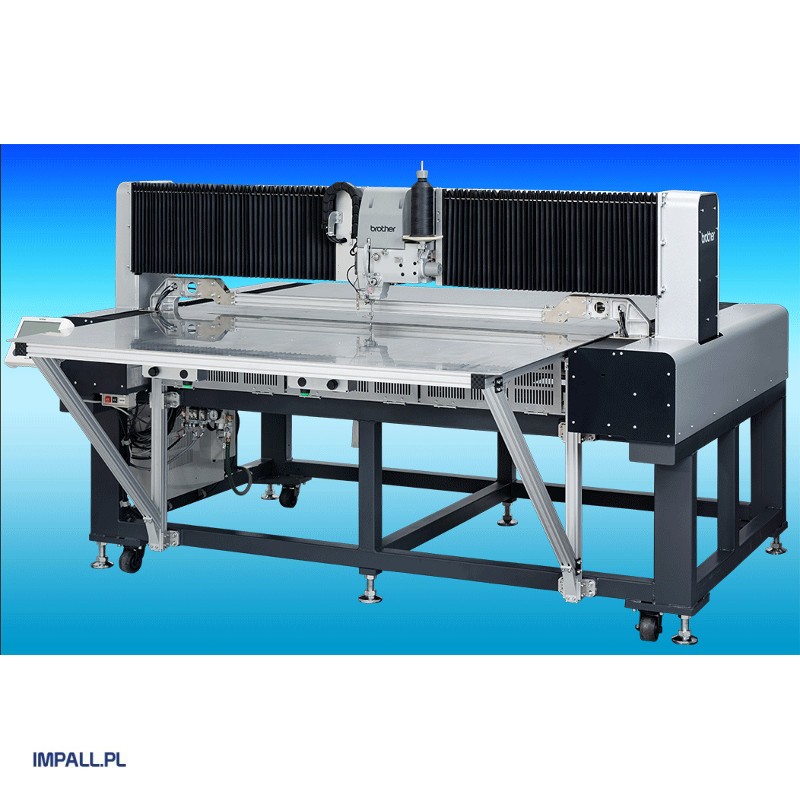

BROTHER BAS-375H

FRAME MACHINE FOR AUTOMATIC SEWING OF PROGRAMMED PATTERNS 1200 x 700 mm

Description

Description

Innovative Automatic Machine for Sewing Pre-Programmed Patterns within the Available Sewing Area

An innovative automatic machine for sewing pre-programmed patterns within the available sewing area. The modified machine design has minimized its size, thus saving installation space. The machine features a movable head along the X-axis and material movement along the Y-axis through a pressing frame. This construction enhances stitching accuracy and quality, regardless of the pattern being sewn, as the head is always positioned in the sewing direction.

Ideal for repeated stitching of patterns such as reinforcements, decorative stitching, and attaching handles or clasps, it excels in multi-layer sewing of heavy materials, such as transport straps and container bags. It is also perfect for attaching tapes, Velcro, labels, and decorative stitches.

A powerful servo motor (550W) provides greater needle penetration force on thick materials, even at lower sewing speeds. The new transport mechanism design improves pattern quality, offers smoother operation, enhances precision, and reduces start and stop times.

Machines are equipped with a modern NEXIO-based panel:

- 7-inch touch display

- easy program editing

- control manipulator for easier operation

- simple program selection, new program creation, and storage

- SD card reader and USB ports

- self-diagnosis system with error display

Increased needle penetration force and stabilized material support enhance stitch quality with consistent thread tension.

Sewing Parameters:

- Work area: 1200 x 700 mm

- Sewing speed: 2,500 stitches/min

- Stitch length: 0.05 – 20.0 mm

- Maximum stitches per program: 100,000

- Maximum programs: 999

- Maximum presser foot lift: 95 mm (head lift height up to 70 mm)

- Double-capacity hook

- Needle cooling system

- Thread break sensor

- Electronic programmable thread tensioner

- SD memory card reader

- Two USB ports

- Operating pressure: 0.5 MPa

- Weight: 910 kg

Requires connection to compressed air.

Additional information

Additional information

| Brand |

|---|