- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

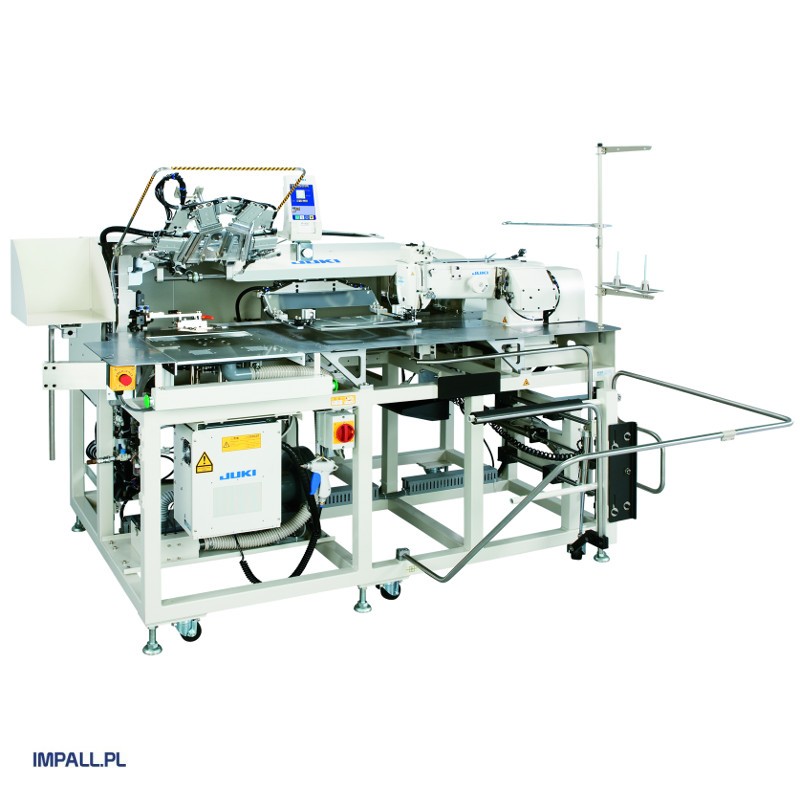

Next-generation, high-performance automatic machine, electronically controlled by stepper motors and servo motors, for attaching pockets to jeans, workwear, etc. The pocket sewing process is fully automated. The operator’s task is limited to placing the pocket (without needing to pre-press the pocket edges) on a special form, positioning the base material, and initiating the sewing process. The machine automatically folds the pocket edges, transports the folded pocket to the work area, and sews it according to the programmed pattern, including reinforcing bartacks. The machine is equipped with a stacker that collects the finished piece with the pocket sewn on. During the sewing cycle, the operator can prepare the next pocket, significantly increasing work efficiency. An option is available for attaching a label under the pocket.

Optionally, the machine can attach both the pocket and the pocket flap in a single operation.

The estimated productivity of the machine is approximately 2,237 pockets/8 hours (assuming a two-needle stitch with two bartacks); productivity increases with single-needle stitching. All operating parameters are configured via an easy-to-use touch panel.

Quick and easy form change for different pocket shapes. Form change time is under 5 minutes without the need for specialized tools.

The active electronic needle thread tension setting can be programmed in the sewing pattern, adjusting automatically based on the thickness of the sewn material layers.

Technical Specifications:

- Sewing speed: 4,000 stitches/min

- Number of needles: 1

- Maximum sewing area: 250 x 250 mm

- Stitch length: 0.1 – 6.0 mm

- Memory capacity: 999 pocket patterns

- Power supply: 230V

- Air consumption: 220 l/min

- Working pressure: 5 kg/cm²

- Needles: 132 (standard Nm130)

- Weight: 558 kg

Requires connection to compressed air.

Additional options available:

- Barcode reader

- Laser marker