- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

SNAP FASTENERS AND PRESSES

Handheld Snap Fastener Press

With a handheld snap fastener press, you can easily attach snaps, rivets, and buttons to your textile products. The handheld snap fastener presses we offer are compatible with various pressing attachments, making them versatile tools. Not only do they effectively and securely fasten metal accessories, but they can also assist in creating holes in the material. This is especially useful when you need to cut perfect circles for later covering with buttons. It’s also worth exploring the buttonhole machine for this purpose. The handheld snap fastener press is relatively lightweight and features a comfortable handle that ensures smooth and even pressing and fastening of metal elements without causing unsightly deformations. A handheld snap fastener press is ideal for home use or small tailoring workshops where metal accessories are used but not in large quantities.

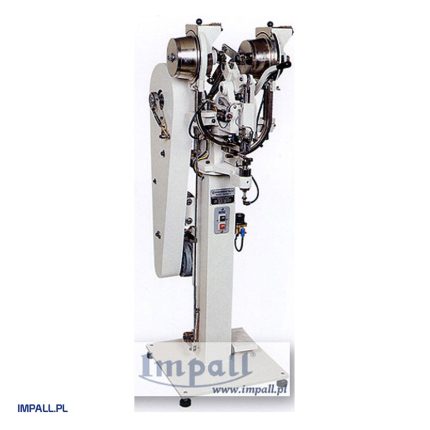

Pneumatic Snap Fastener Press

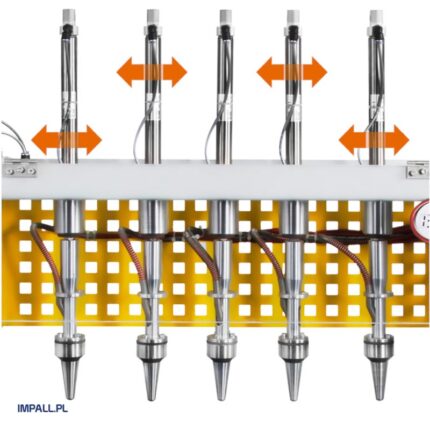

The situation is different with other types of snap fastener presses. A pneumatic snap fastener press is a highly professional device used in large tailoring, leather goods, and sewing factories. A pneumatic snap fastener press significantly speeds up the process of attaching snaps, buttons, or hooks. It doesn’t rely on manual labor but instead uses a compressor. However, it’s not fully automated—the pneumatic snap fastener press is operated using foot pedals by the operator. The pressure applied by the operator causes the press to work with compressed air (usually several bars, depending on the model). Pneumatic snap fastener presses can be equipped with more than one head with pressing attachments, allowing the production process to be accelerated as there is no need for constant changing of pressing attachments.

Automatic Snap Fastener Press

An automatic snap fastener press is another type of device. These presses have feeders that are loaded with metal components. Automatic snap fastener presses also operate using compressed air, but they automatically feed the snap parts. Additionally, they allow for precise positioning of the material so that the distance from the edge of the fabric is consistent. Importantly, automatic snap fastener presses come in two separate machines—one for male parts and another for female parts of the snaps. In our offer, you will find professional snap fastener presses that will greatly streamline your daily work. If you are currently outfitting your workshop or sewing room, we also recommend considering sewing machines such as straight stitch machines, including double-needle models, overlock machines, and buttonhole machines, which will further speed up the production process while maintaining the highest quality.