- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

PNEUMATIC PRESSES

Pneumatic Presses for Precise and Fast Garment Pressing

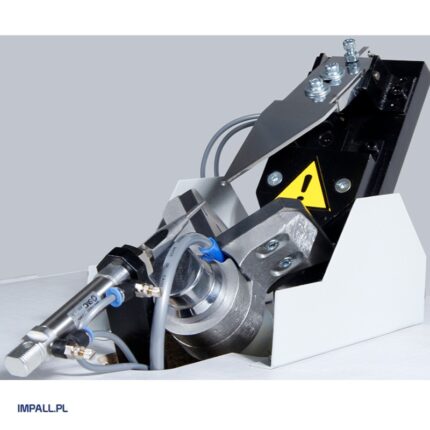

Sometimes, irons simply aren’t enough. Even with an attached steam generator, they may not deliver the required efficiency, especially due to the small size of their soleplate, which hinders the quick ironing of large fabric pieces. Fortunately, pneumatic presses are here to help. Their primary function is to smooth out the fabric using two key factors. The first is pressure, as the material is placed between the working surfaces of the pneumatic press. The second factor is either high temperature or steam. The use of a press is safe for fabrics, making it an excellent method for preparing garments before distribution.

General Purpose and Specialized Pneumatic Presses

At Impall, you’ll find universal pneumatic presses that are suitable for all types of garments. Many of these machines are made by Rotondi, one of the most renowned manufacturers of ironing equipment. In addition to these, we also offer specialized pneumatic presses. Each is designed for a specific purpose: some are for trouser legs, others for jackets, and some are used for shaping the upper parts of trousers. Although these specialized presses take up some space, their specific focus allows them to significantly speed up the garment preparation process. Some even come with steam generators, allowing garments to be perfectly shaped and smoothed within minutes.

Universal Design of Pneumatic Presses

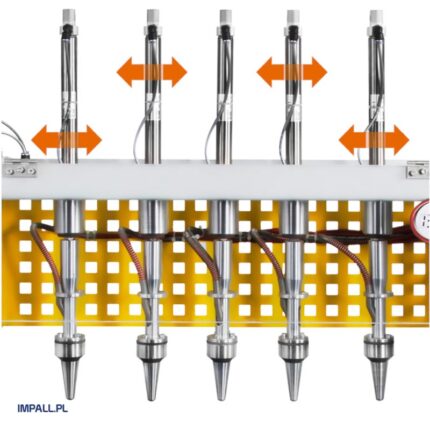

The universal and stable scissor-like design of our pneumatic presses ensures an ideal finish. The steaming and suction functions provide the highest quality pressing, essential for any clothing company. The application of innovative technologies in these presses guarantees easy and quick fabric placement, greatly accelerating the pressing process.

Tailored Presses to Meet Your Needs

Our professional pneumatic presses, designed for various applications, are perfect for any workshop. In our selection, you’ll find computer-controlled pneumatic presses for simultaneously pressing inner and outer seams on both the left and right trouser legs, presses for shaping collars on jackets, and many more. All of these machines are easy to operate and highly reliable.

Impall also offers a wide range of other ironing equipment. Among them, you’ll find professional irons, steam generators, and vertical ironing devices that allow you to press garments without removing them from hangers. We also offer ironing tables, including those equipped with steam generators. If you are involved in garment or textile production, be sure to check out our industrial sewing machines – including lockstitch machines, overlock machines, and bartacking machines.