- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

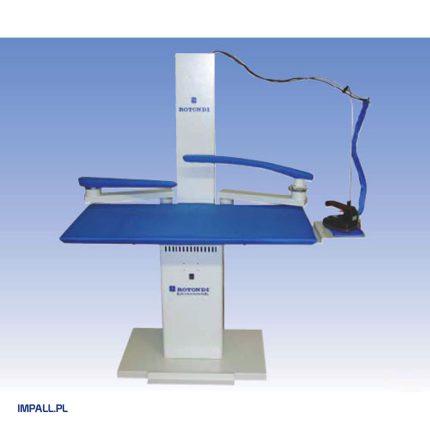

IRONING TABLES

Ironing Tables and Their Significant Role

Ironing tables are an essential component in the equipment of professional tailoring studios, sewing workshops, and beyond. These tables prove highly beneficial in hotels, restaurants, cafes, laundries, clothing manufacturers, retail clothing stores, and more. This is due to the efficiency of the ironing process when using an ironing table, which directly impacts work comfort, ironing speed, and the overall quality of the final product. Ironing tables play a critical role in the complex process of producing clothing and other textile products. The fabric ironing process is not just about achieving the final result—what ironing is often associated with—but also about enhancing the entire process of designing, sewing, and modeling products. A smooth, perfectly ironed fabric is easier to cut precisely, fit, and measure, making the overall sewing process more accurate.

Ironing tables are a solution aimed at achieving a high level of aesthetic quality in product execution. They are an indispensable element of a professional tailoring workstation, especially in industrial operations.

What Do Ironing Tables Offer?

Modern, advanced ironing tables offer a large working surface, proper lighting, adjustable height, and pneumatic control. But that’s not all. High-quality ironing tables come with a range of additional functionalities. There are ironing tables with heated working surfaces, steam generators, powerful suction systems, and exhaust chimneys for venting air. Some ironing tables also have a blow function. Innovative ironing tables allow for the installation of two irons, with adjustable iron stands and the option to install various pressing shapes. This makes ironing tables highly versatile. Additional presses are available for jackets, blazers, shoulder finishing, yokes, and sleeves. Some ironing tables come with irons, usually two: one dry and one steam iron, along with a steam generator. We recommend ironing tables from reputable brands with extensive experience in the tailoring industry. Using an ironing table ensures effective seam smoothing, inserting interfacings, and shaping flaps and belts.

Basic Types of Ironing Tables

Ironing tables can be categorized into the following groups:

– Standard ironing tables – the simplest versions (also suitable for home use);

– Foldable ironing tables;

– Ironing tables on wheels;

– Ironing tables with an integrated suction system;

– Mobile ironing tables, on wheels;

– Ironing tables with electric heaters, and more.

In conclusion, investing in ironing tables is an investment in your business that will significantly enhance the aesthetics and efficiency of tailoring processes.