- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

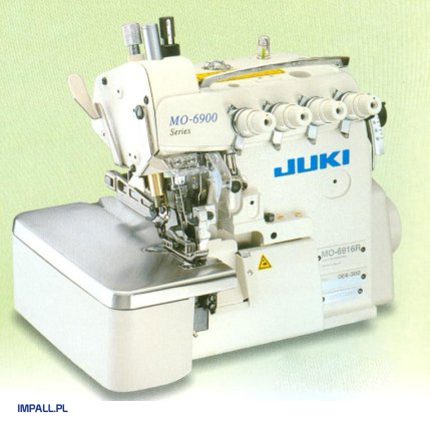

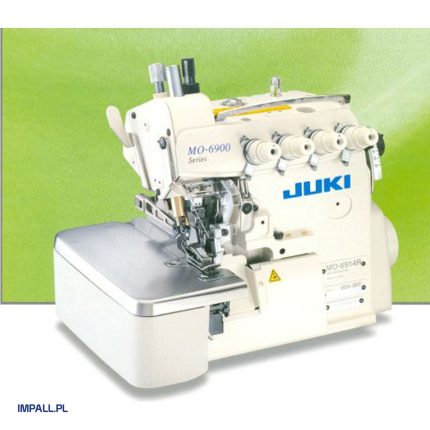

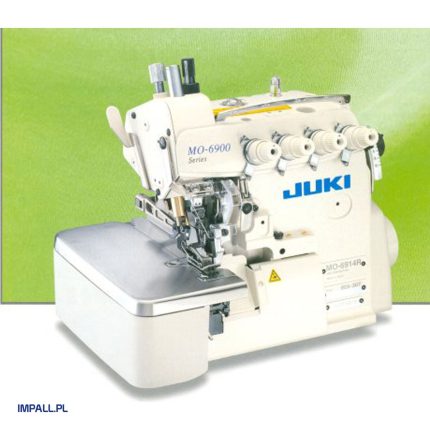

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

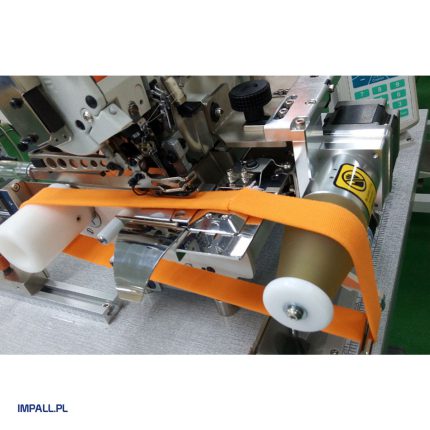

Overlock Machines with Dual Feed

Industrial Overlock Machines with Dual Feed – No More Challenges with Denim, Leather, or Upholstery Fabrics

If you need a strong and reliable machine, industrial overlock machines with dual feed are an excellent choice. Working with thick, heavy materials such as denim, leather, upholstery fabrics, or workwear textiles requires demanding sewing techniques. These materials don’t easily yield to standard handling, often requiring cross-stitching, dealing with thick seams, and managing material bulges. This is where industrial overlock machines with differential dual feed (serrated and presser foot feed) come into play, designed to provide maximum comfort when working with challenging materials.

What Does Differential Feed Offer in an Overlock Machine? Practical Applications of Industrial Overlock Machines with Dual Feed

Differential feed in industrial overlock machines refers to the separate adjustment of the front and rear feed dogs to achieve the desired effect. With differential feed, you can prevent fabric puckering when overcasting edges or avoid stretching and waving along the fabric’s edge. The key is adjusting the speed of the front and rear feed dogs, which allows you to control fabric stretch and prevent puckering. With industrial overlock machines equipped with dual differential feed, you can effectively handle both highly elastic, stretchable materials and delicate tulles, as well as thick fabrics.

Medium and Heavy Sewing – Which Industrial Overlock Machine is Best?

If you specialize in medium or heavy sewing, we recommend investing in professional machines like industrial overlock machines with differential dual feed (serrated and presser foot feed). This will ensure a high level of comfort and efficiency when working with demanding materials. Additionally, consider a 2-5 thread overlock machine, which offers a wide range of stitch options. An additional feature to look for is the rolled hem stitch (mereżka) with easy switching in the overlock machine, a highly practical function frequently used in workshops.