- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

Overlock Machines with Automation

JACK C7-5-M04/435

In stock

SIRUBA 747KST-514M3-24/VT/SD/RLS

In stock

SIRUBA 747KS-514M3-24/LF-D6A

In stock

Effective Automation of Sewing Processes – Industrial Overlock Machines with Automation

Industrial overlock machines with automation play a crucial role in building the competitiveness of a sewing workshop in the active market for sewing services. Overlock machines with automation are designed to minimize the operator’s involvement in repetitive, routine tasks. Additionally, they help to significantly reduce human errors.

What Do the Latest Overlock Machines with Automation Offer?

A high-quality industrial overlock machine with automation is equipped with a powerful, energy-efficient motor built into the machine’s head, along with proper ventilation for optimal performance. Moreover, an automated overlock machine primarily automates tasks such as needle positioning, thread trimming, speed regulation (and thereby stitch length), presser foot pressure adjustment, stitch selection, lower looper threading, quick return to factory settings, and more. Some of the latest overlock machines even feature a voice guidance system to assist and guide the operator. An intuitive and easy-to-read control panel is also essential when selecting such a machine.

Overlock Machines with Automation Offer Three Operating Modes:

1. **Manual Mode**: Operated with a foot pedal.

2. **Semi-Automatic Mode**: Partially operated with the help of photocells.

3. **Fully Automatic Mode**: Entirely automated operations.

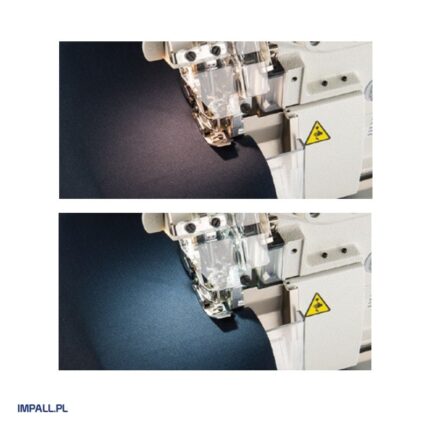

It’s worth noting that photocells operate with high precision, which contributes to the accuracy of the automated processes in such an overlock machine. Photocells are typically located in the needle plate, without reducing the operator’s working area. This setup significantly increases productivity in the sewing production process.

Long-Term Investment in Efficiency and Comfort

Investing in overlock machines with automation is a long-term strategy to enhance work efficiency, increase production capacity, accelerate processes, and improve workplace comfort.