- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

Overlock Machines for Light Sewing

Industrial Overlock Machines for Light Sewing – Which Ones Work Best in Large Sewing Workshops?

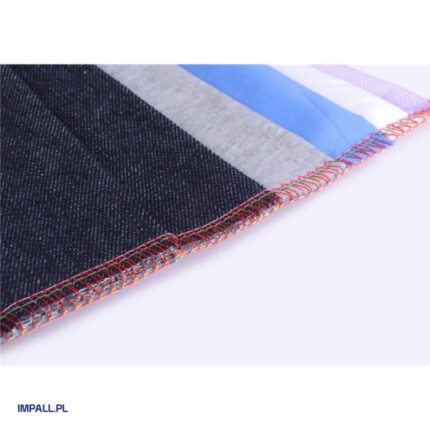

Overlock machines for light materials are undoubtedly among the essential sewing machines in any workshop, serving as a fundamental part of their equipment. These machines are relatively versatile, allowing for both stitching and overcasting fabrics for decorative, functional, or protective purposes. It is crucial to ensure that industrial overlock machines for light sewing are equipped with the latest sewing machine motors—energy-efficient, quiet in operation, and well-ventilated. This will ensure the long lifespan of the overlock machines for light materials, save up to 75% in energy compared to traditional motor technology, and significantly improve workflow.

What to Consider When Choosing Industrial Overlock Machines for Light Fabrics?

When selecting an overlock machine for light sewing, it’s important to consider technical specifications, personal preferences, and the types of sewing tasks you perform. Key features to look for include:

– Needle positioning

– Presser foot pressure adjustment

– Sewing speed (ideally in the range of 5,500-6,000 stitches/min)

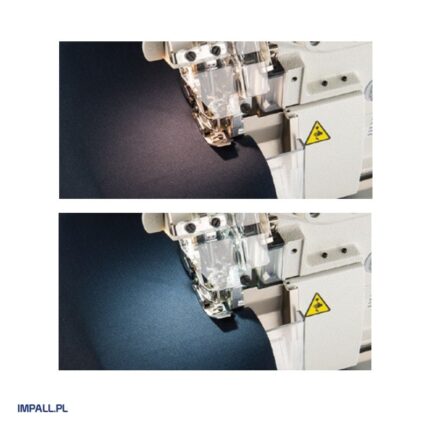

– Integrated LED workspace lighting

– Intuitive and user-friendly control panel

– Equipped with a comfortable sewing table and other additional accessories.