- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

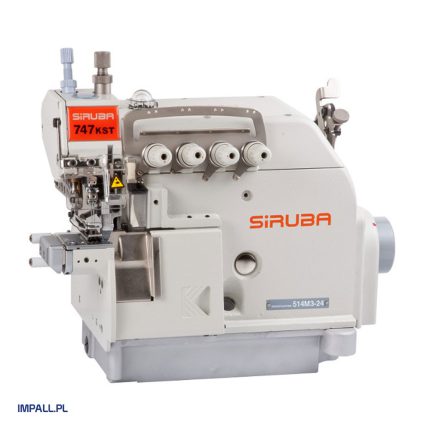

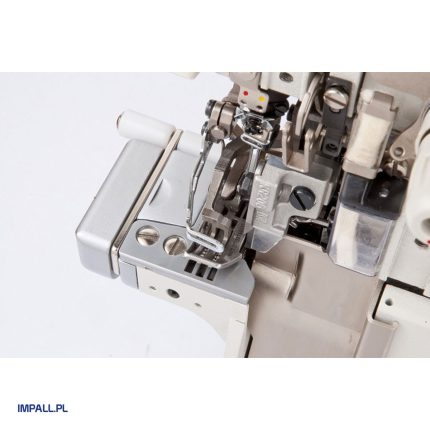

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

Cylindrical Overlock Machines

Industrial Cylindrical Overlock Machines – What Are They and How Are They Used?

Industrial cylindrical overlock machines are specially designed sewing machines intended for circular or round sewing tasks. As the name suggests, these machines feature a cylindrical, round bed design, enabling them to effectively sew closed, circular sections, often with relatively narrow diameters.

Enhancing Sewing Processes – Investing in Industrial Cylindrical Overlock Machines

In the rapidly advancing world of technology, implementing solutions that streamline sewing and tailoring processes is essential. Investing in the right equipment, such as industrial cylindrical overlock machines, is both practical and invaluable. These machines excel at sewing closed circuits like sleeve cuffs, pant legs, and even attaching elastic bands or ribbing to garments—tasks that are both repetitive and regular in the sewing industry.

Key Technical Features of a Good Cylindrical Overlock Machine

Cylindrical overlock machines typically operate with 3-4 threads and feature a bottom feed dog transport mechanism, making them ideal for light to medium sewing tasks. They are a valuable addition to any sewing workshop. When choosing a cylindrical overlock machine, consider key technical features such as:

– Stitch speed (ideally reaching up to 8,000 stitches per minute)

– Adjustable stitch width (preferably with at least 3-4 options)

– Adjustable stitch length, among other functionalities