- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

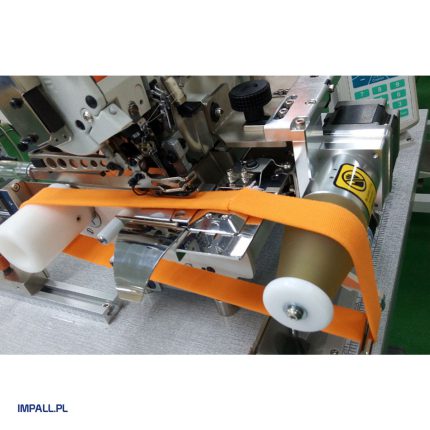

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

Overlock – Create Secure Stitches

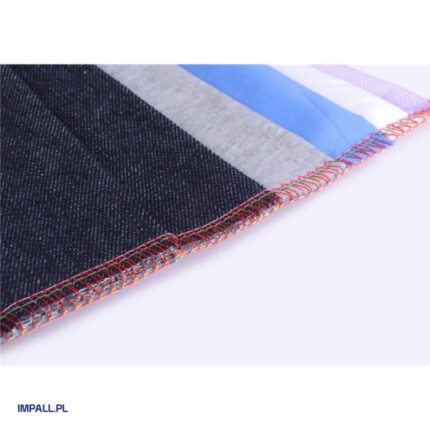

The most popular models include the Juki overlock and the Siruba overlock. Their main function is to “serge,” that is, to create a stitch that secures the fabric edges to prevent fraying. Overlocks offer great versatility in creating various stitches, one of the most interesting being the rolled hem stitch. This stitch allows the overlock machine to fold the fabric edge and finish it automatically, providing a very elegant appearance without the need for additional folding. Therefore, if you often serge materials or join multiple fabrics together, an overlock sewing machine is undoubtedly what you need. The machine uses the overlock stitch, creating it on the fabric’s edge, which not only reinforces it but also protects the fabric’s edge during use.

What’s the Difference Between a 4-Thread Overlock and a 5-Thread Overlock?

Overlock sewing machines on the market can easily be categorized based on the number of threads they use. In our store, you can even find 5-thread overlocks. This type of machine uses two needles, and the resulting fabric seam is extremely durable. Using fewer threads, of course, results in a more elastic stitch, but its protective function is somewhat reduced. It’s also important to note that multifunctional sewing machines, typically intended for home use, usually create a 2-thread overlock stitch. Meanwhile, industrial overlocks create stitches using 3 to 5 threads. A 3-thread overlock stitch is much more durable than the one produced by a multifunctional sewing machine with an overlock function. Additionally, a 4-thread or 5-thread overlock stitch is not only very durable but also adds decorative elements that directly enhance the aesthetic quality of the stitch. Our offer includes not only typical types of overlocks, up to 5-thread overlocks from manufacturers like Juki and Jack, but also machines with features like automatic chain stitching, such as the Siruba overlock, which can reduce standard manual tasks by up to three times. We also offer many other subcategories of overlocks and specialized machines like buttonholers and eyelet machines for special tasks in your sewing workshop.

4-Thread or 3-Thread Overlock: What’s the Difference Between These Types of Stitches?

4-thread overlocks are crucial sewing machines that allow the use of a stitch with 4 threads. They engage 2 needles (right and left) and both loopers (upper and lower). The role of the right needle is to further strengthen the stitch’s durability. This stitch is characterized by high resistance, being the strongest of the overlock stitches, and it doesn’t break; instead, it stretches appropriately. It is very elastic. Remember to properly adjust the thread tension in a 4-thread overlock.

- SIRUBA Overlocks

The 3-thread overlock stitch is also commonly used. It serges the edges of seams, protecting them from fraying. In this case, two loopers and one needle are engaged. You can choose a simple 3-thread stitch or one with additional folding or rolling of the fabric. The latter stitch uses significantly less thread, but the former provides a very strong seam. Both stitches in a 4- or 3-thread overlock are primarily used in garment production: leggings, T-shirts, skirts, dresses, etc.

Which Other Stitch is Particularly Functional in an Overlock?

Another very useful stitch is the so-called “flatlock” stitch. In many overlock models, it is possible to purchase a flatlock attachment. This overlock stitch is created using 1 needle and 2 loopers. The thread binding occurs on the underside of the fabric, leaving the fabric edge neatly rolled or folded.

Overlocking vs. Sewing Machine?

An overlock is quite a different sewing device than a traditional sewing machine. It primarily serves to finish the fabric, that is, to serge its edges. What other visible differences exist between a sewing machine and an overlock? Overlocks used in professional tailoring workshops have built-in knives (top and bottom) that cut the fabric edges or the excess thread protruding from the edge before the stitch is created on the fabric. Moreover, for example, every Juki overlock, whether 5-thread or another type, has an adjustable knife cutting depth, which affects the stitch width. Sewing machines with an overlock function generally do not have this feature, and in the few exceptions that do, it is much less effective.

Industrial Overlocks and Differential Feed

Industrial overlocks ensure that even elastic fabrics or knits pose no problems during sewing, thanks to their differential feed system. This system means that each machine has two feeds under the presser foot, which can operate independently—at different speeds. Industrial overlocks are also significantly faster.

Lack of a Bobbin Winding Thread in Overlocks

Overlocks do not have a bobbin-winding thread—there is no rotary or oscillating hook under the needle plate (no place to insert a lower thread bobbin). Instead, two metal loopers work below (a 5-thread overlock has three), which are threaded with threads from large spools placed at the back. The first points through which the threads must be threaded are called masts. They enable sewing with 2 to 5 threads simultaneously.