- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

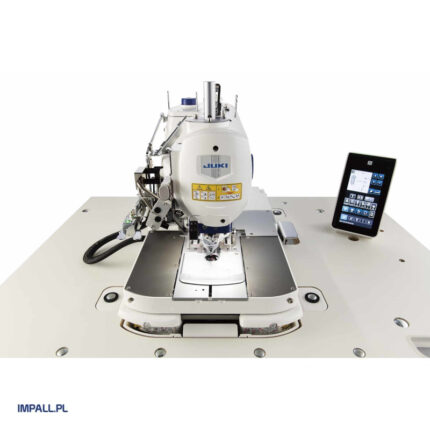

BUTTONHOLING MACHINES

Buttonhole Machine – When Is It Worth Using?

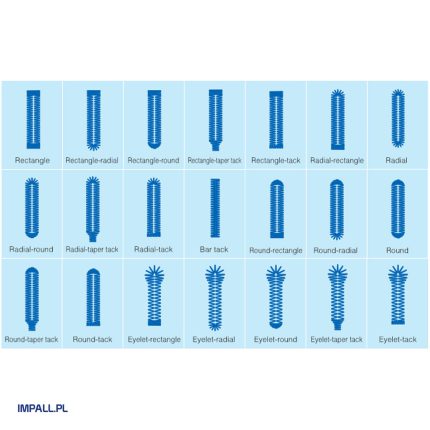

One of the common sewing machines frequently used in the apparel industry is the buttonhole machine. Its primary function is to create and finish buttonholes in fabrics. Buttonhole machines can be programmed to create holes in various shapes and sizes, making them indispensable in the textile industry. When used correctly, they can significantly increase the speed of production, thereby contributing to a real reduction in the costs associated with garment or other textile manufacturing. It’s also worth mentioning other popular sewing machines that enhance productivity and work quality, such as overlocks, lockstitch machines, and zigzag machines. In the following description, we will explain what a buttonhole machine is and suggest when it might be worth using one.

What Is a Buttonhole Machine Used For?

In general terms, a buttonhole machine is a specialized industrial machine designed to create buttonholes in fabric. It can automatically cut the fabric or knit and then neatly stitch around the cut edges. Typically, professional industrial buttonhole machines are automatic, two-thread devices that sew with a lockstitch. For hobbyist sewers, a professional buttonhole machine might be less practical and cost-effective. In such cases, a traditional multifunctional sewing machine equipped with a buttonhole foot would be a better option. Depending on the model of the home sewing machine, it may be possible to create buttonholes automatically or semi-automatically. If you’re planning to make individual garments, even a machine offering semi-automatic buttonhole stitching will be sufficient.

Any potential increase in sewing time will likely be insignificant. However, when it comes to serial production, home sewing solutions are bound to be entirely unprofitable.

Even in small tailoring workshops producing very short series, it’s advisable to use professional equipment. An industrial buttonhole machine offers a high sewing speed, which, depending on the model, can exceed 4,000 stitches per minute.

Advantages of Modern Buttonhole Machines

Modern buttonhole machines are industrial machines that feature advanced technological solutions. Most models available on the market are equipped with energy-efficient servo motors, which help significantly reduce the energy costs associated with sewing. Additionally, for some time now, buttonhole machines with operational panels featuring graphic displays have been available. These displays make the machine much easier to operate and allow the program to be fully customized to the user’s specific needs.

Another major convenience is the automated thread tension control system, which adjusts for different parameters during parallel sewing and when locking the buttonhole.

Buttonhole Machines by Brother, Juki, Jack, and More at Impall

Our store offers buttonhole machines from the most well-known manufacturers. Among them are both mechanical and electronically controlled devices. Regardless of the type of buttonhole machine, their parameters can be easily adjusted, either through knobs or the included panel. If you know what you need from your future buttonhole machine, contact us—we’ll help you choose a model that meets your requirements.