- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

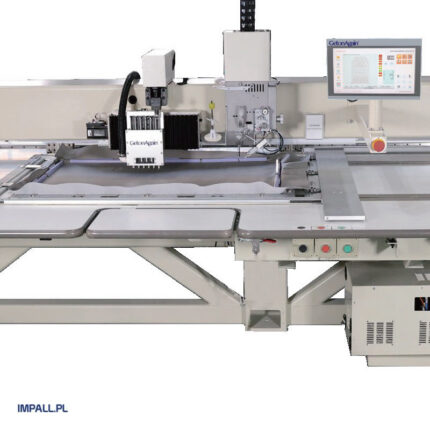

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

JUKI AMS224ENHS/JEUX0043

In stock

JUKI LU-2818ESAL-7-SC922/CP180

In stock

JUKI LU-2818AL-7-SC922/CP180

In stock

JUKI LU-2868ALD-7-SC922/CP180

In stock

Industrial Sewing Machines – A Brief History

Industrial sewing machines have a rich and complex history. The first inventors of sewing machines aimed to replicate hand sewing, as this was the traditional method of joining materials and making seams. The early machines were designed to mimic the hand movements of a person sewing. However, this approach ultimately did not succeed. The breakthrough came in 1830 when Barthelemy Thimonnier created and patented the first industrial sewing machine. He focused primarily on designing appropriately shaped needles for the machine, moving away from the need to imitate hand movements. Although these machines had many shortcomings, and the seam was formed on the underside of the fabric rather than the top, Thimonnier established a sewing workshop with 80 stations equipped with these first industrial sewing machines. Over the years, inventors competed to introduce new innovations and technical improvements, leading to today’s industrial sewing machines, which are highly durable, easy to operate, and significantly more efficient. This evolution has also influenced and advanced other aspects, such as cutting room equipment and the clothing design process, which now often involves specialized software.

What Distinguishes Industrial Sewing Machines?

First and foremost, modern industrial sewing machines are entirely different from home sewing machines. They are significantly more efficient, faster, larger, and, due to the high repetition of tasks, are often designed to perform only specific functions on the production line. The differences mainly arise from the intended use of the machines—industrial machines are used in sewing factories, often operating 24/7, while home machines are used on a much smaller scale, in private homes, and are often more multifunctional.

The Construction of an Industrial Sewing Machine

Depending on the model and purpose, industrial sewing machines vary in design but share several common components:

– Motor: Drives the flywheel, which, in turn, moves other elements responsible for sewing.

– Speed regulator: Typically in the form of a pedal.

– Presser foot: Allows for sewing different stitches and is one of the most important elements of industrial sewing machines.

– Feed mechanism: Moves the fabric during sewing, facilitating the sewing process.

– Stitch plate: Made of metal, with a bobbin containing the lower thread underneath it.

– Bobbin case: Holds the bobbin with the lower thread and plays a crucial role in forming the stitch by gathering the thread.

– Upper thread tensioner: Located in the upper part of the machine housing, it controls the quality of the stitching and seam.

– Free arm: Designed to assist in sewing hard-to-reach areas.

– Housing: Depending on the model, it may be made of metal or plastic.

In addition to these features, industrial sewing machines often include advanced technologies, such as stepper motors and specialized software, enabling the sewing of even the most intricate patterns on fabric surfaces.

Renowned Manufacturers of Sewing Machines: Siruba, Juki, Jack, Brother

Our selection includes all the leading brands of industrial sewing machines. We offer devices from manufacturers such as JUKI, BROTHER, JACK, SIRUBA, MERROW, JAPSEW, and many others. We provide complete equipment for sewing workshops, cutting rooms, and other production or service facilities. At Impall, we specialize in distributing a wide range of machines, including highly specialized equipment like auto-lap machines, emblem sewing machines, and pleating automats. We invite you to explore our full range of products.

Siruba Industrial Sewing Machines – A Brand from Taiwan

Siruba, established in 1965, produces professional and innovative sewing machines characterized by integrity. Siruba is a globally recognized brand favored by many professionals in the tailoring industry. Siruba industrial sewing machines represent the highest technology, ensuring that every sewing task is performed with exceptional professionalism. These machines are also easy and intuitive to operate, making sewing fast, efficient, and enjoyable. The Siruba brand offers various sewing machines, including overlocks, lockstitch machines, coverstitch machines, and specialized machines such as bar tackers and button sewing machines. Siruba industrial sewing machines are known for their quality, reliability, and advanced technology, along with post-sales service that can be provided based on the machine’s unique identification number.