- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

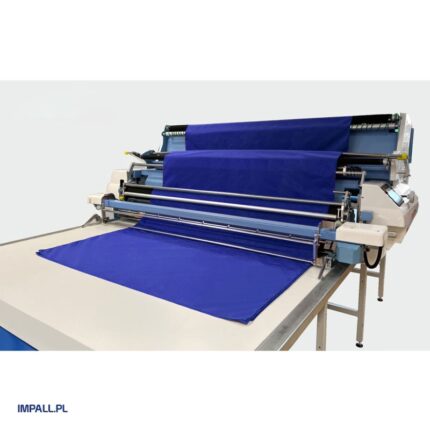

SPREADING SYSTEMS

Manual and Automatic Fabric Spreaders

Fabric spreading, the process of layering fabrics into a stack, is crucial for cutting operations. Without it, templates would need to be placed on each layer of fabric individually before cutting, which would significantly slow down the process. Therefore, fabric spreading should not be overlooked. However, the process is more complex than it might initially seem. First, the fabrics must be of the same length as the first layer, where the templates are placed. Second, they should be evenly tensioned. Third, it’s not just the length of the fabrics that matters, but also the uniform placement of one layer on top of the other. Without this, it’s impossible to properly prepare for cutting. Given these demands, it’s wise to use fabric spreading systems that ensure all layers in the stack are perfectly aligned and of identical length.

At Impall, you’ll find both manual and automatic fabric spreaders. Manual spreaders require operators—ideally two for ease of use. On the other hand, automatic spreading systems independently layer the fabrics. These machines are equipped with features such as edge sensors and automatic cutting tools for trimming each layer. They also come with control panels that allow you to set all the necessary parameters for spreading.

Long-Lasting Fabric Spreading Systems

Cutting tables and fabric spreaders are essential equipment in cutting rooms of tailoring and upholstery workshops, where they are becoming increasingly popular. It’s difficult to imagine a well-equipped professional cutting room without a fabric spreader. These systems allow for precise fabric spreading and accurate cutting of elements using cutting tools. High-quality spreading systems are indispensable in any cutting room.

Versatile Fabric Spreading Options with Spreaders

The fabric spreading systems we offer are selected based on your needs. Depending on the type of material, they provide precise control over the spreading parameters. Most fabric spreaders are equipped with the aforementioned automatic edge sensor and layer trimmer. Our range includes automatic, semi-automatic, and manual fabric spreaders. We also offer other essential cutting room equipment, including fabric rewinders, trimmers, as well as band knives, rotary knives, and vertical knives. If you frequently work with large stacks of fabric, an automatic cutting machine (cutter) will undoubtedly be a valuable addition.