- 1-NEEDLE LOCKSTITCH MACHINES

- Lockstitch Machines with Dual Feed (Needle and Bottom Feed)

- Lockstitch Machines with Dual Feed (Bottom and Presser Foot Feed)

- Lockstitch Machines with Triple Feed (Bottom, Presser Foot, and Needle Feed)

- Lockstitch Machines for Light and Medium Materials

- Lockstitch Machines for Medium and Heavy Materials

- Lockstitch Machines with Automatic Needle Positioning

- Lockstitch Machines with Automatic Thread Trimming

- Lockstitch Machines with Automatic Backtacking

- JACK lockstitch machines

- SIRUBA lockstitch machines

- JUKI lockstitch machines

- BROTHER lockstitch machines

- KRAFFT lockstitch machines

- 2-NEEDLE LOCKSTITCH MACHINES

- OVERLOCKS

- 5-Thread Overlock Machines

- 4-Thread Overlock Machines

- 3-Thread Overlock Machines

- Overlock Machines for Light Sewing

- Overlock Machines for Heavy Sewing

- Overlock Machines with Dual Feed

- Overlock Machines with Automation

- Cylindrical Overlock Machines

- Overlock Machines with Electronic Automation

- Pneumatic Automation Overlock Machines

- JACK Overlock Machines

- SIRUBA Overlock Machines

- JUKI Overlock Machines

- PEGASUS Overlock Machines

- BARTACKING MACHINES

- ZIG-ZAG MACHINES

- BUTTON SEWING MACHINES

- BUTTONHOLING MACHINES

- INTERLOCK MACHINES

- CHAINSTITCH MACHINES

- FEED OF THE ARM MACHINES

- BLIND STITCH MACHINES

- AUTOLAP MACHINES

- SEWING AUTOMATIC MACHINE

- SPECIAL MACHINES

- HEAVY SEWING MACHINES

- DECORATIVE STITCH MACHINES

- SEAMLESS MACHINES

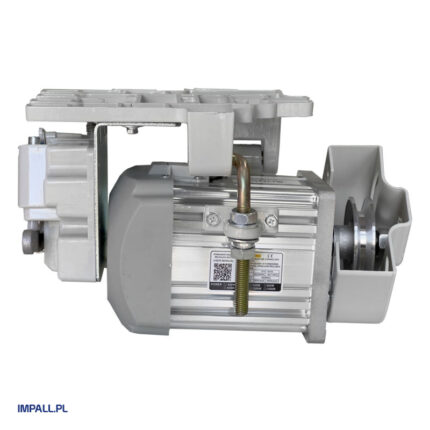

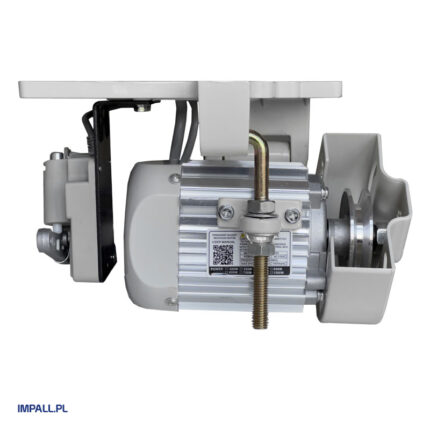

SEWING MACHINE MOTORS

Motor for Industrial Sewing Machine

A powerful and energy-efficient motor for a sewing machine is often crucial for its long-term, trouble-free operation. This is the key and most important component, so it’s definitely worth choosing the most technologically advanced and highest quality units. Moreover, a modern motor in a sewing machine enhances work comfort, which directly translates into increased productivity and efficiency in the production process. Additionally, new-generation motors are primarily energy-efficient, which plays a very important role in cost optimization.

Energy-Efficient Servo Motors vs. Clutch Motors in Sewing Machines

The servo motors for sewing machines available in our store operate much more quietly than their clutch motor counterparts. While the noise from a single motor may not be overly bothersome, in sewing rooms with a dozen or even several dozen machines, the motors can drown out the sound of the sewing machines themselves. Investing in newer motors not only reduces noise levels but also lowers energy consumption. Servo motors for sewing machines do not run continuously when plugged in but only operate when the pedal is pressed. In contrast, clutch motors run continuously, though at varying intensities.

Depending on the work being done on the sewing machine, servo motors allow you to set the maximum number of revolutions per minute. This makes them suitable for both fast overlock machines and slower sewing of heavy materials. The speed in modern sewing machine motors can be precisely controlled with the pedal. The servo motors for sewing machines in our store also come with a positioner, which allows the needle to stay in the upper or lower position, significantly easing and speeding up the work.

Energy-efficient servo motors are compatible with many sewing machines. However, there are still machines for which clutch motors are more appropriate. Additionally, some may prefer to use clutch motors in their sewing machines due to familiarity. Therefore, we also offer clutch motors, including low-speed options for machines like blind stitch machines and two-needle straight stitch machines, as well as high-speed options used in overlock machines and coverstitch machines.